What is Bending and Its Types? A Guide for Engineers and Students

Bending is a fundamental concept in material science and engineering, playing a crucial role in industries ranging from construction to manufacturing. Whether you’re a student just starting to explore mechanical principles or an engineer looking to refine your understanding, bending is a topic worth mastering.

bending basics, including definitions, its types, and the factors that influence it. We’ll also explore real-world applications to help you understand its importance in engineering and manufacturing processes.

Introduction to Bending

At its core, bending occurs when a force is applied to a material causing it to curve or deform along an axis. Think about what happens when you flex a plastic ruler or bend a metal bar. Bending work can significantly change a material’s shape while maintaining its structural integrity if done correctly.

At E S HAJI & CO., we specialize in precision bending processes, ensuring that materials meet the rigorous demands of various industries. But why is bending so important?

Why Bending Matters in Engineering

Bending is vital for designing and manufacturing components such as beams, plates, and pipes. Without bending, creating curved components for bridges, cars, or even aircraft would be nearly impossible. It allows materials to take on new shapes while retaining strength and reliability, making it essential for innovation in engineering and construction.

Fundamentals of Bending

To understand bending, you need to grasp three essential concepts: stress, strain, and the neutral axis.

Stress and Strain in Bending

When a material bends, it experiences two primary forces:

- Compression occurs on the side where the material is pressed inward.

- Tension occurs on the opposite side, where it’s stretched outward.

The material deforms due to these opposing forces, creating strain. If the forces exceed the material’s limit, plastic deformation or a permanent bend can occur.

The Neutral Axis

Between the compression and tension zones lies the neutral axis, where no stress or strain is present. This is the pivot point during bending. The material above the neutral axis compresses, while the material below it stretches.

Understanding the neutral axis is pivotal for precise bending work, like beam or pipe bending, ensuring structural stability.

Types of Bending

Now that we’ve covered the fundamentals, let’s explore the different types of bending. Each has unique characteristics, applications, and effects.

1. Pure Bending

Pure bending occurs when a material is subjected to a constant bending moment without any shear force along its length.

Key Features:

- Typically observed in beams under uniform loads.

- Only tension and compression take place, no lateral forces.

Examples:

- Bending of a beam in the middle when supported at both ends.

- Applied in mechanical frameworks requiring symmetrical load distribution.

2. Simple Bending

Occurs when a beam bends due to forces applied perpendicular to its axis, creating uneven stress distribution.

Key Features:

- Found in real-world scenarios like cantilever beams or overhanging structures.

- Stress distribution varies depending on load placement.

Examples:

- A streetlight bending under wind pressure.

- Loading of wooden planks supported on one end.

3. Unsymmetrical Bending

Unsymmetrical bending happens when the plane of loading does not align with the principal axis of a cross-section.

Key Features:

- Produces complex stress patterns.

- More challenging to analyze compared to pure or simple bending.

Examples:

- Aircraft wing structures subjected to asymmetric loads.

- Curved beams in bridges.

At E S HAJI & CO., we excel in precision bending processes, from simple to advanced unymmetrical bending. Our expertise ensures every component meets exact engineering specifications.

Factors Affecting Bending

Several factors influence a material’s behavior during the bending process, making material selection and process design crucial in engineering.

1. Material Properties

- Materials with high tensile strength, like steel, resist bending but do not deform easily.

- Ductile materials, like aluminum, bend more easily but may require added care to prevent fracturing.

2. Thickness and Cross-Section

- Thin materials bend more easily than thick ones.

- I-beams and hollow sections are strategically designed to optimize bending resistance while minimizing weight.

3. Load Type and Distribution

- Uniform loads lead to even bending, while point loads create localized bends.

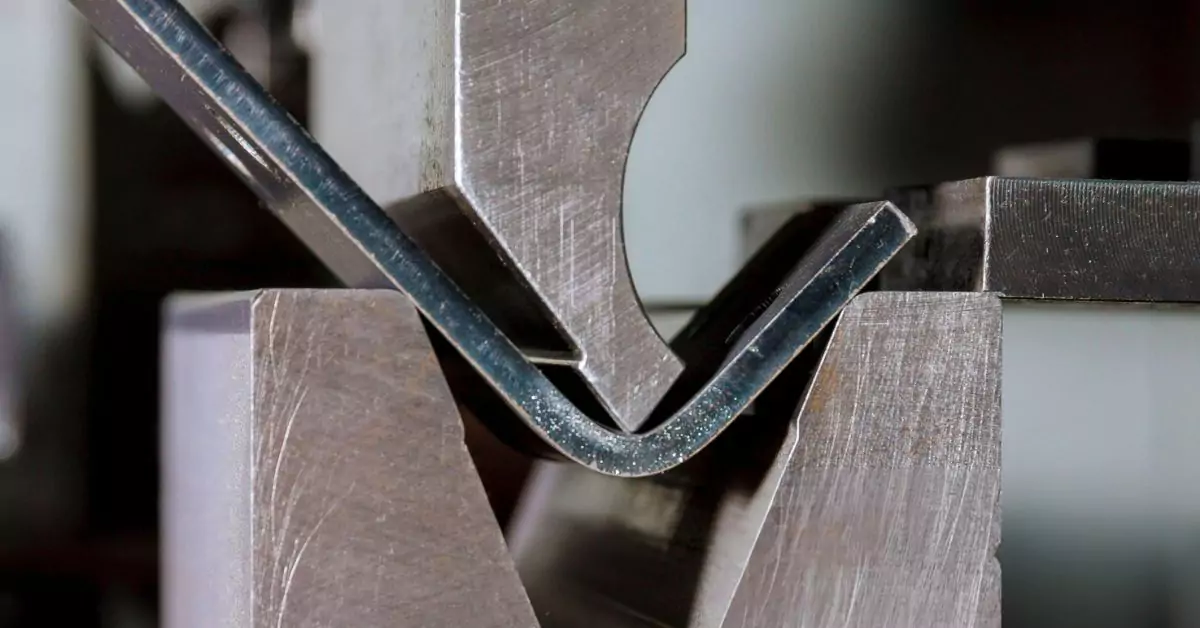

- Dynamics such as the angle and speed of bending also affect outcomes in processes like press-brake bending.

4. Temperature

- Heating materials can make bending easier and reduce strain, especially in metals. Techniques like hot bending are widely used in industries like shipbuilding and automotive manufacturing.

Applications of Bending in Engineering

Bending is a versatile process used across various industries. Here are some real-world applications illustrating its importance.

1. Construction and Infrastructure

Building frameworks, bridges, and pipelines rely on precisely bent steel beams and bars to meet specific design and weight requirements.

2. Automotive and Aerospace

From car chassis to aircraft wing components, bending is crucial for optimizing strength, aerodynamic performance, and durability.

3. Furniture and Appliances

Chairs, tables, and even household appliances incorporate bent metal and wood components for aesthetic appeal and functionality.

4. Manufacturing and Production

In production lines, bending processes help create parts like brackets, hooks, and frames quickly and efficiently.

5. Custom Engineering Projects at E S HAJI & CO.

We recognize that every project is unique. That’s why we provide tailored bending solutions for industries ranging from manufacturing to large-scale infrastructure projects.

Summary and Further Learning Resources

Mastering bending principles is essential for any engineer, material scientist, or student aiming to excel in their field. Understanding the types of bending, the fundamental mechanics, and the factors influencing the process offers a strong foundation for tackling real-world engineering challenges.

Interested in learning more or looking for expert guidance? The team at E S HAJI & CO. is here to help! Reach out to us for customized bending work, from simple sections to complex geometries.