Understanding Flange Weight Chart for Optimal Selection

In the realm of construction and manufacturing having a clear understanding of the specifications for the flanges is vital. This article explores the weight charts of flanges, their dimensions, and how they are used aiding you in making informed choices.

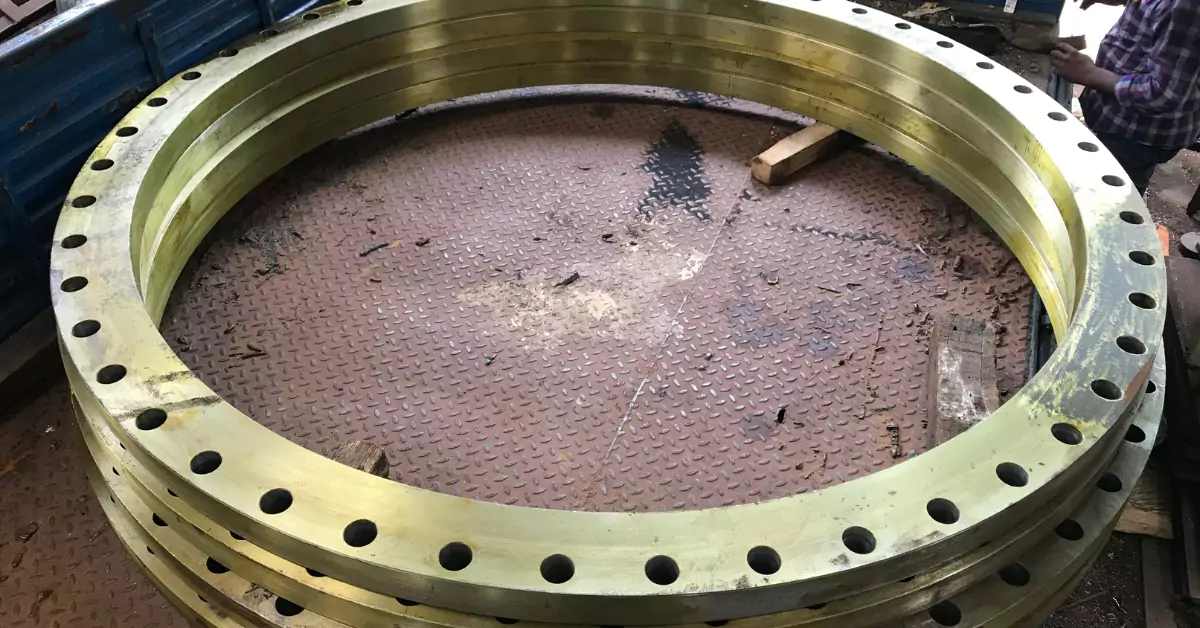

What is a Flange?

A flange can be described as a device used to connect two pieces of equipment. They create a secure seal, which allows the flow of fluids in pipe systems. The knowledge of the dimensions and weight of flanges are essential to making sure that they are compatible and stable in application.

Types of Flanges

Flanges are available in a variety of kinds, such as:

- Weld Neck Flanges

- Slip-On Flanges

- Blind Flanges

- Socket Weld Flanges

- Lap Joint Flanges

Each kind serves a particular function and comes with distinct sizes and weights.

Importance of Flange Weight Charts

Flange Weight Chart are essential details about the weight of various varieties of flanges, in relation to their measurements and materials. The information provided is crucial for the following reasons:

- Calculation of Load: Making sure that the piping system is able to accommodate the weight of Flanges and the materials being transported.

- Material Choice Materials: Different types of types of materials (stainless steel carbon steel) can have different weights and characteristics.

- Shipping Costs: Knowing the weight of a package can assist in estimating shipping costs and handling expenses.

Flange Weight Chart Overview

Common Flange Classes

Flanges can be classified by their pressure ratings. For instance:

- Class 150

- Class 300

- Class 600

Flange Dimensions Chart

This is a table that has been simplified for Classes 150 and 300 flanges.

| Flange Class | Nominal Pipe Size (NPS) | Outside Diameter (mm) | Weight (kg) |

|---|---|---|---|

| Class 150 | 1″ | 108 | 1.2 |

| Class 150 | 2″ | 133 | 2.3 |

| Class 300 | 1″ | 108 | 1.4 |

| Class 300 | 2″ | 133 | 2.7 |

Flange Weight Calculation

For calculating the weight of an flange, make use of the following formula:

Weight=VolumexDensity\text = \text \times \textWeight=VolumexDensity

- Volume is calculated by with the help of the flange.

- Density is different for each material (e.g. carbon steel, stainless steel, etc.).

Flange Weight Calculator Tools

A variety of online tools are able to help in determining the weight of a flange:

- MS Flange Weight Calculator: An instrument specifically designed that measures the mass of steel flanges made from mild steel.

- ANSI Flange Weight Chart: provides weight information to ANSI standards.

Frequently Asked Questions

What’s the difference in Class 150 and Class 300 Flanges?

Class 150 flanges have the ability to be used with lower pressure than Class 300 flanges. They are made for more pressure requirements.

What is which flange is appropriate for my project?

Take into consideration factors like the pressure rating, temperature as well as the kind of fluid and its the compatibility of the material with the piping.

How can I locate precise flange weight charts?

The most comprehensive charts are often located in handbooks for engineers as well as industry standard documents such ASME B16.5 as well as specific catalogs of flange manufacturers’ catalogues.

Conclusion

Knowing about flange weight charts is crucial for engineers, manufacturers and contractors. By having the correct details, you will be able to ensure that you are operating safely and efficiently of your pipe systems. If you require more information about Flange sizes and weights, please call ES HAJI & CO, Flange Manufacturers in Chennai.

Flange Weight Chart

Explore comprehensive Flange Weight Chart and dimensions to choose the right flange for your project.

Product Brand: ES HAJI AND CO

Product Currency: INR

Product Price: 100

Price Valid Until: 2024-12-31

Product In-Stock: InStock

5