Introduction to Bending Allowance

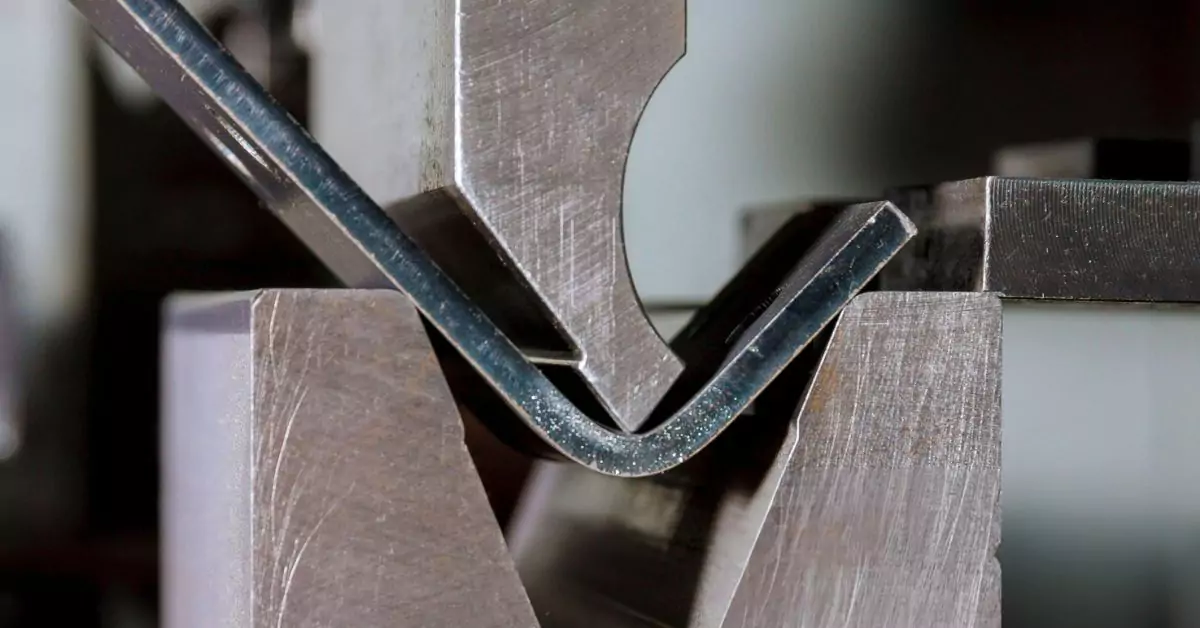

In the world of sheet metal fabrication, bending is one of the most fundamental processes. However, bending doesn’t merely alter the shape of the metal; it also impacts its dimensions. This is where bending allowance becomes critical. Bending allowance refers to the amount of material required to account for the elongation that occurs when a sheet metal material is bent.

When metal is bent, the outer surface stretches, and the inner surface compresses, causing changes in the dimensions of the sheet. Accurate calculation of the bending allowance ensures the final part meets design specifications, avoids material waste, and optimizes cost — a major consideration when evaluating the sheet metal price per kg.

Key Factors Affecting Bending Allowance

Several factors influence bending allowance in the sheet metal process, including:

- Material Properties: Different materials, such as aluminum sheet metal fabrication or stainless steel sheet metal fabrication, behave differently under stress. For example, aluminum is more flexible than steel, requiring less bending force.

- Sheet Metal Thickness: The thickness of the metal significantly impacts the bending allowance. Thicker metals like those used in large sheet metal fabrication require larger allowances.

- Bend Angle and Radius: The sharper the bend angle, the greater the allowance needed to prevent cracking or deformities.

- Fabrication Method: Techniques like CNC sheet metal fabrication provide higher precision in calculating and executing bending allowances.

The Importance of Bending Allowance

The Importance of Bending Allowance

Bending allowance is an integral part of the sheet metal fabrication process flow chart. It directly impacts:

- Precision: Proper calculation ensures the final product dimensions are accurate. This is particularly important for precision sheet metal fabrication.

- Material Efficiency: Avoiding errors minimizes material waste, which is vital for cost-conscious projects like sheet metal fabrication services market or industrial sheet metal fabrication.

- Cost Optimization: Accurate calculations can reduce the overall fabrication cost, making the process more economical.

For businesses in competitive markets, like sheet metal fabrication in Bangalore or sheet metal fabrication companies in Chennai, precision and cost efficiency are key differentiators.

Bending Allowance in the Fabrication Process

The process of incorporating bending allowance involves specific steps:

- Material Selection: Choosing the right sheet metal material, whether for ss sheet metal fabrication or aluminium sheet metal fabrication, ensures compatibility with the design.

- Thickness Calculation: Using tools like a sheet metal fabrication cost calculator, manufacturers estimate the material needed for the bend.

- Fabrication Tools: Advanced machinery like sheet metal fabrication machines or CNC machines for sheet metal fabrication is employed for precise cutting and bending.

- Design Adjustments: Engineers modify the design to accommodate bending allowance, ensuring accurate dimensions post-fabrication.

Applications of Bending Allowance

Bending allowance is critical in various sheet metal fabrication services, including:

- Custom Sheet Metal Fabrication: Used in creating unique parts for industries like automotive and architecture.

- HVAC Sheet Metal Fabrication: Ensures proper fit and function for ductwork and other components.

- Sheet Metal Fabrication Projects: Enables the efficient production of parts with complex bends.

Challenges and Solutions in Bending Allowance

Challenges and Solutions in Bending Allowance

Despite its importance, calculating bending allowance can be challenging. Factors like inconsistent sheet metal thickness or variations in sheet metal fabrication tools can affect accuracy. However, modern solutions such as:

- Sheet Metal Fabrication Software: These tools allow for detailed planning and simulation of the bending process.

- Precision Tools and Equipment: Heavy sheet metal fabrication projects benefit from advanced machinery.

For businesses like sheet metal fabrication companies near me, these solutions ensure consistent quality.

Why Choose E S HAJI & CO for Sheet Metal Fabrication?

E S HAJI & CO is a trusted name in the sheet metal fabrication industry, offering:

- Expertise in precision sheet metal fabrication near me.

- Advanced tools for sheet metal fabrication works, including sheet metal fabrication laser cutting.

- Comprehensive services for custom metal fabrication, bending sheet metal fabrication, and more.

Their commitment to quality makes them one of the best sheet metal fabrication providers in the market.

Understanding bending allowance is essential for achieving precision and efficiency in the sheet metal fabrication process. By considering factors such as sheet metal thickness, material properties, and fabrication techniques, manufacturers can produce high-quality components. For reliable and cost-effective solutions, trust E S HAJI & CO to meet all your sheet metal fabrication needs with expertise and professionalism.

Bending Allowance

E S HAJI & CO offers premium sheet metal fabrication services, including stainless steel sheet metal fabrication, aluminum sheet metal fabrication, and custom sheet metal fabrication near me. With state-of-the-art sheet metal fabrication machines and a dedicated team, we deliver precise and cost-effective solutions for industrial and custom projects.

Product Brand: E S HAJI And CO

Product Currency: INR

Product In-Stock: InStock

5