What is the Stamping Process? Everything You Need to Know

Stamping is an extraordinary art and industrial process that combines precision, creativity, and technology to create remarkable products. From custom artwork to large-scale industrial components, the stamping process has revolutionized numerous industries.

Whether you’re an artisan shaping your next masterpiece, a DIY enthusiast looking to elevate your projects, or an industrial designer aiming for efficiency and innovation, understanding the stamping process is a game-changer.

What is the Stamping Process?

The stamping process is a manufacturing technique that involves compressing or shaping materials, typically metal or paper, using specialized tools and a stamping machine. By applying pressure with a die, artisans and manufacturers can create intricate designs, shapes, or functional components with precision and detail.

Think about the last embossed wedding invitation you received, the intricately designed leather wallet you own, or even the parts of your car’s engine—these are all products of stamping. The beauty of this method is its ability to deliver consistency while allowing for artistry and customization.

A Historical Glimpse into Stamping

A Historical Glimpse into Stamping

The origins of stamping date back thousands of years to ancient civilizations. Early artisans and blacksmiths used rudimentary tools to engrave metals and create decorative designs. From the intricacies of coins in the Roman Empire to the beautifully crafted armor in medieval times, stamping evolved alongside technological advancements. The Industrial Revolution marked a significant turning point for stamping. Mechanized stamping machines replaced manual labor, exponentially increasing production capabilities.

Why Stamping Matters Across Industries

The stamping process is more than just a manufacturing technique—it’s a backbone for countless industries. Here’s why it stands out:

- Efficiency: Stamping machines speed up production while maintaining high precision, making it ideal for mass production.

- Customization: From unique artisan goods to branded industrial components, stamping allows for endless design possibilities.

- Durability: Stamped products boast remarkable durability, ensuring they withstand wear and tear.

- Cost-Effectiveness: Once a stamping die is created, the cost per product decreases significantly, making it economically viable for both small-scale artists and large industries.

Key Steps in the Stamping Process

Understanding the steps involved in the stamping process sheds light on how versatile and intricate this approach truly is. While the specifics may vary, here’s a general breakdown:

- Design Creation: Every stamping project begins with a design or blueprint. This step focuses on mapping out the dimensions, details, and specifications of the final product.

- Material Selection: Choosing the right material—metal, leather, or paper—is pivotal. The material’s thickness, texture, and durability will impact the final result.

- Die Preparation: The die is a custom tool used in the stamping machine to imprint or cut the desired shape/design. It’s created precisely to match the project requirements.

- Stamping Process: The stamping machine applies calculated pressure to shape, emboss, or cut the material as required.

- Inspection and Finishing: After stamping, the product undergoes inspection and any necessary finishing touches, such as deburring edges or polishing surfaces.

Types of Materials Used in the Stamping Process

One of the great strengths of stamping is the wide range of materials it accommodates. Here’s a look at the most common ones:

- Metals (Steel, Aluminum, Brass): Perfect for industrial components like automotive parts or detailed artisan jewelry.

- Leather: Often used for embossing designs into luxury goods such as wallets or handbags.

- Paper and Cardstock: Adds elegance to invitations, packaging, and branding materials.

- Plastic and Acrylic: Used for flexible designs in signage and decorative accessories.

The choice of material depends on the intended function, aesthetic preferences, and the tools available.

Tools and Technology in Modern Stamping

Tools and Technology in Modern Stamping

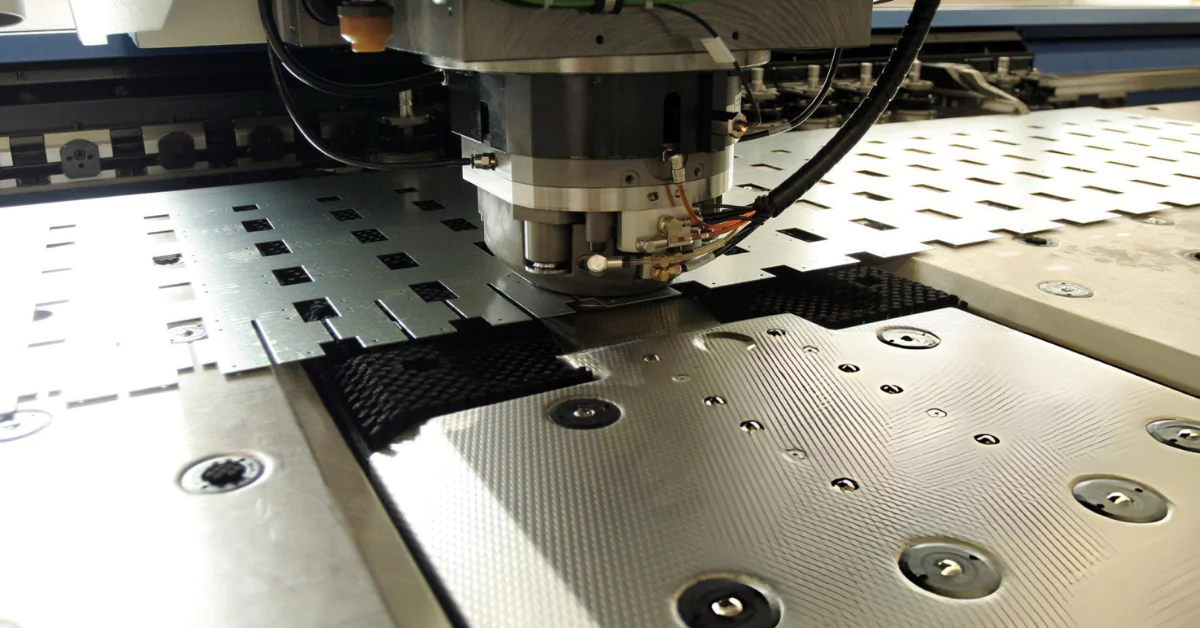

Modern stamping wouldn’t be possible without breakthroughs in equipment and technology. The heart of the process lies in the stamping machine, and there are several types to choose from:

- Mechanical Presses: Utilized for rapid stamping in high-volume industrial applications.

- Hydraulic Presses: Preferred for delicate and detailed work due to their precise pressure control.

- CNC Stamping Machines: These computer-driven machines offer unparalleled precision and are perfect for intricate designs.

Additionally, 3D printing and digital design software have revolutionized die creation, reducing preparation time while increasing design complexity.

Challenges in Stamping—and How to Overcome Them

Every process comes with its own set of challenges, but problems in stamping often lead to creative solutions:

- Material Wear and Tear: Modern stamping machines now adjust pressure to minimize damage to materials without sacrificing quality.

- Tooling Costs: While traditional tools can be costly, innovations like reusable dies and modular stamping systems are providing cost-effective alternatives.

- Precision Issues: Advanced technology, like CNC systems, ensures unparalleled accuracy, even for complex designs.

With the right equipment and techniques, these hurdles can be easily tackled.

Innovations and Trends in Stamping

The stamping industry has embraced innovation to stay relevant and impactful. Some current trends include:

- Sustainability: Using recycled materials and optimizing processes to reduce waste.

- Laser-Assisted Stamping: Combining laser technology for even more refined and complex designs.

- Integration with AI and IoT: Leveraging real-time data from smart stamping machines to improve production efficiency.

- Customization on Demand: Advanced machines now allow artisans and customers to request one-off, hyper-personalized designs.

Applications for Artisans, DIY Enthusiasts, and Designers

The versatility of stamping can’t go unnoticed, especially for our creative community!

- For Artisans: Stamping elevates craftsmanship, making it possible to create intricate patterns on metals, leather, and more. Think custom jewelry or artisan notebooks.

- For DIY Enthusiasts: Personalize your projects with embossed stationery, monogrammed leatherwork, or unique wall art. The possibilities are endless!

- For Industrial Designers: Stamping provides a reliable method for replicating functional, high-quality components for machinery, vehicles, and architecture.

By incorporating stamping into your workflow, you have the tools to make products that stand out for their precision and artistry.

Where the Future of Stamping is Headed

The stamping process is far from static. With continued advancements in technology and sustainable practices, this ancient art form is set to play an even bigger role in both artistry and industry. Whether you’re a seasoned artisan or just stepping into the world of crafting, understanding the nuances of stamping can give you a competitive edge.

Are you ready to experiment with stamping in your work? If so, consider investing in a quality stamping machine to bring your ideas to life. Want to learn more about tools and materials that align with your project vision? Reach out today!