CNC Oxyfuel & Plasma Cutting: Revolutionizing Metal Processing

In the modern manufacturing and construction industries, precision, efficiency, and consistency are more important than ever. Cutting and shaping metal has traditionally been labor-intensive, time-consuming, and prone to errors. However, with the advent of CNC Oxyfuel and Plasma Cutting technologies, metal processing has undergone a remarkable transformation. E.S Haji & Co., a pioneer in industrial metal fabrication, leverages these advanced technologies to deliver high-quality results across a wide range of industries.

What is CNC Oxyfuel Cutting?

CNC Oxyfuel cutting is a process that uses a combination of oxygen and fuel gases to cut through thick metal sheets. Controlled by a Computer Numerical Control (CNC) system, this method allows precise cutting based on digital designs.

The process involves heating the metal to its ignition temperature and then applying a stream of pure oxygen to burn through the material. CNC control ensures the cut follows the exact dimensions of the design, reducing errors and material wastage.

Benefits of CNC Oxyfuel Cutting include:

- Ability to cut thick metals efficiently.

- High precision and accuracy.

- Faster production rates compared to manual cutting.

- Reduced material wastage.

At E.S Haji & Co., CNC Oxyfuel cutting is used for heavy steel plates, structural components, and industrial projects where precision and strength are critical.

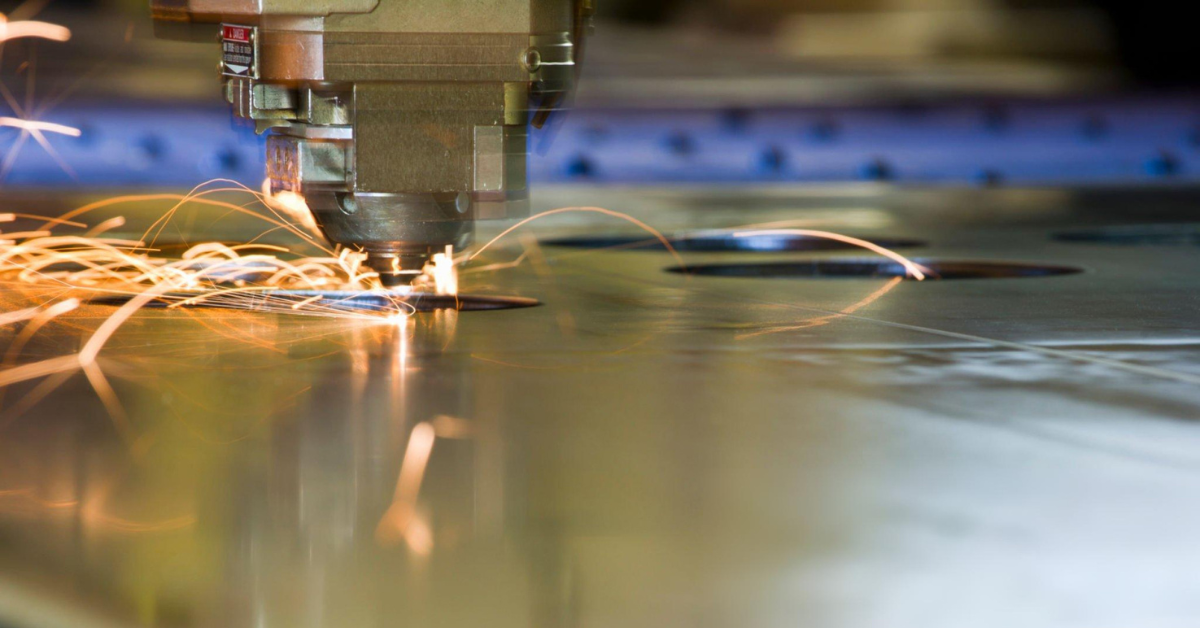

Understanding CNC Plasma Cutting

CNC Plasma Cutting uses an ionized gas (plasma) to melt and cut through electrically conductive metals such as steel, stainless steel, aluminum, and copper. The CNC system guides the cutting torch along the desired path, allowing for intricate shapes, patterns, and high-quality edges.

Unlike oxyfuel cutting, plasma cutting can work on thinner metals with extreme precision and minimal heat-affected zones, making it ideal for components that require fine detailing.

Key advantages of CNC Plasma Cutting include:

- Exceptional precision for intricate designs.

- Smooth edges with minimal finishing required.

- Faster processing speeds for thinner metals.

- Versatility across multiple metal types.

E.S Haji & Co. utilizes CNC plasma cutting to handle both large-scale industrial projects and custom fabrication orders, ensuring each component meets the highest standards.

Why CNC Cutting Technologies Are Revolutionizing Metal Processing

Both CNC Oxyfuel and Plasma Cutting have transformed metal fabrication in several ways:

- Enhanced Accuracy – CNC systems follow digital blueprints with pinpoint precision, ensuring each cut is consistent, reducing human error.

- Increased Efficiency – Automated cutting speeds up production timelines, allowing businesses to meet tight deadlines without compromising quality.

- Complex Designs Made Simple – Intricate patterns, curves, and holes can be executed with ease, something traditional cutting methods struggle to achieve.

- Cost-Effective Production – Reduced material wastage and minimal rework lead to significant cost savings.

- Safety Improvements – Automation reduces the need for manual intervention, minimizing workplace accidents associated with manual cutting.

At E.S Haji & Co., adopting CNC cutting technologies ensures that clients receive precise, durable, and cost-effective metal components tailored to their unique requirements.

Applications Across Industries

E.S Haji & Co. serves multiple industries by leveraging CNC Oxyfuel and Plasma Cutting technologies. Applications include:

Construction and Infrastructure: Structural steel beams, plates, and customized components for buildings and bridges.

- Oil and Gas: Heavy-duty plates, flanges, and pipelines requiring precise specifications.

- Shipbuilding: Components that need intricate cuts and consistent quality.

- Automotive and Machinery: Fabrication of specialized parts with tight tolerances.

- Custom Industrial Fabrication: Unique projects requiring a combination of precision, speed, and reliability.

The flexibility of CNC cutting allows E.S Haji & Co. to cater to both large-scale industrial projects and highly specialized custom orders.

Why Choose E.S Haji & Co. for CNC Cutting Services

With decades of experience in metal fabrication, E.S Haji & Co. combines industry knowledge with cutting-edge CNC technologies to deliver superior results. Their skilled team ensures:

- High-quality cuts with minimal errors.

- On-time project delivery.

- Custom solutions tailored to client needs.

- Adherence to international quality and safety standards.

By integrating CNC Oxyfuel and Plasma Cutting into their workflow, E.S Haji & Co. continues to set benchmarks in precision, efficiency, and innovation in metal processing. Experience precision, efficiency, and unmatched quality with CNC Oxyfuel and Plasma Cutting services at E.S Haji & Co., your trusted partner in metal fabrication.