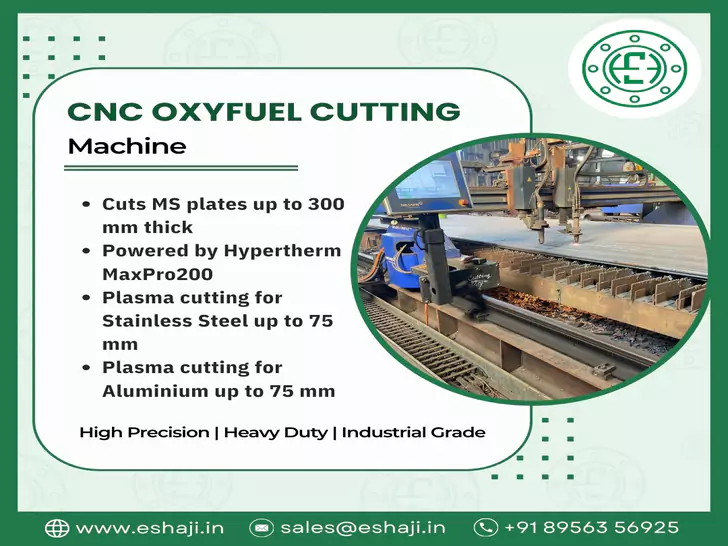

Everything You Need to Know About CNC Oxyfuel Cutting Machines by E S HAJI & CO

Precision and efficiency in metal cutting can make or break projects in industries like manufacturing, construction, and fabrication. One tool that has revolutionized the steel and metal cutting industry is the CNC oxyfuel cutting machine. At E S HAJI & CO., we provide high-quality CNC oxyfuel cutting machines designed to deliver unparalleled performance for your toughest applications.

If you’re exploring CNC oxyfuel, gas, or plasma cutting machines, this comprehensive guide is your go-to reference. Read on to learn about the benefits, applications, key features, and why you should choose E S HAJI & CO. for your cutting machine needs.

What Is a CNC Oxyfuel Cutting Machine?

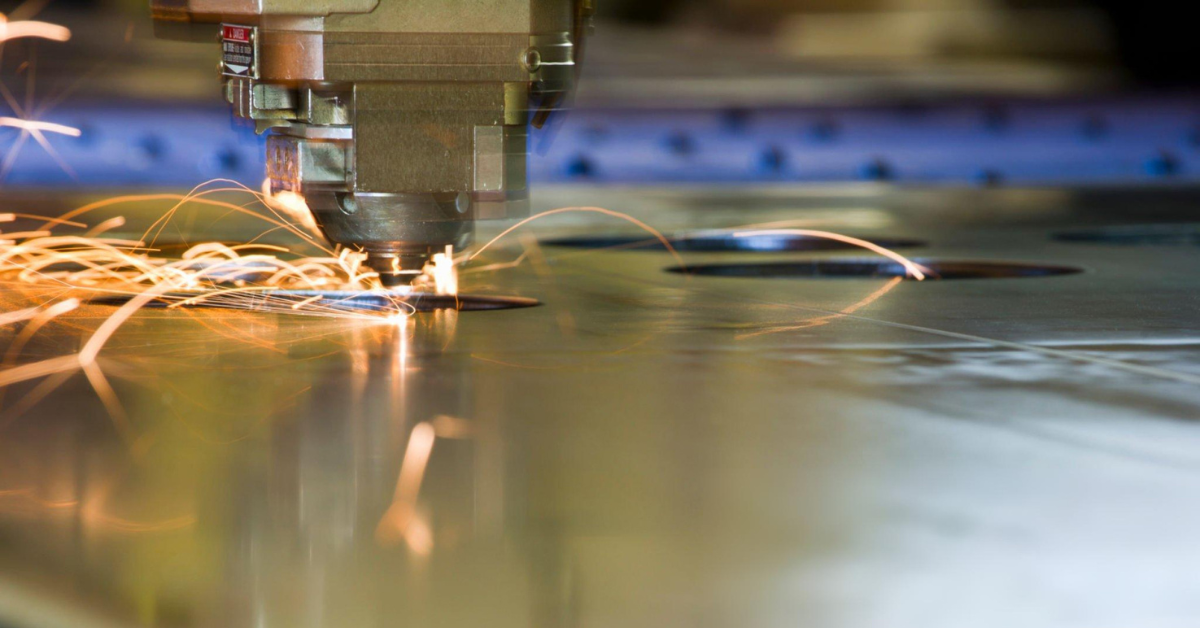

A CNC oxyfuel cutting machine is a computer-controlled cutting system that uses a combination of oxygen and fuel gas to cut through metals like mild steel (MS). The torch generates intense heat (often over 1000°C) to precisely shape metal surfaces. Used across diverse industries, these machines can cut MS plates up to 300 mm thick, tailored to high-production demands.

What sets CNC oxyfuel cutting apart is its automation. CNC (Computer Numerical Control) technology ensures precision, consistency, and minimal human error in cutting operations, making it an indispensable tool in advanced fabrication.

Benefits of Using CNC Oxyfuel Cutting Machines

1. Precision and Accuracy: One of the standout benefits of CNC oxyfuel cutting machines is the unmatched precision they deliver. Thanks to computer-controlled technology, even the most complex designs are executed flawlessly every time. The precise cuts save material and reduce waste, ultimately saving you money.

2. Versatility in Cutting: CNC oxyfuel cutting machines handle an array of cutting tasks. Whether you’re cutting MS plates up to 300 mm thick or incorporating additional plasma cutting capabilities, it’s a one-stop solution for diverse needs. At E S HAJI & CO., our machines are powered by the Hypertherm MaxPro200, enabling plasma cutting for stainless steel and aluminum up to 75 mm thick.

3. Efficiency in High-Volume Cutting: These machines are designed for heavy-duty tasks, ensuring consistently high performance even in high-volume applications. With the right maintenance systems in place, these machines operate at peak performance for a longer life span.

4. Cost-Efficiency: When considering the CNC oxyfuel cutting machine price, take into account its long-lasting value. From precise operations to minimizing material waste, it optimizes every aspect of the cutting process, resulting in significant financial savings.

5. Application-Specific Flexibility: CNC oxyfuel cutting machines can be tailored for different industries and applications. Whether you’re a small-scale workshop or a large manufacturing unit, the machine grows with your needs.

Applications of CNC Oxyfuel Cutting Machines

CNC oxyfuel cutting machines are an essential tool in various industries. Here’s how businesses across sectors utilize their capabilities:

- Construction and Infrastructure: Perfect for cutting MS plates for bridges, buildings, and other large-scale construction projects.

- Manufacturing: Preferred for cutting steel parts used in machinery and tools.

- Shipbuilding: Used to fabricate large, durable steel sections.

- Automotive Industry: Ideal for cutting components for vehicles.

- Fabrication Shops: Cuts plates for custom jobs in signage, furniture, and artistic pieces.

Whether you’re searching for CNC oxyfuel cutting machines for sale or researching CNC plasma cutting machine manufacturers in India, ensuring that your machine meets industry-specific applications is crucial.

Key Features to Look For

When investing in a CNC oxyfuel cutting machine, it’s important to consider the features that affect performance, reliability, and return on investment.

- Material and Thickness Range: A versatile machine should handle multiple thickness levels. For instance, our machines at E S HAJI & CO. can cut MS plates up to 300 mm thick while also performing plasma cutting on stainless steel and aluminum up to 75 mm.

- Advanced Torch Control: Opt for machines with precision torch controls for consistent and accurate cuts. Automation ensures less manual intervention and improved repeatability.

- Powered by Leading Technology: We recommend machines powered by Hypertherm MaxPro200. This ensures top-notch plasma cutting performance, particularly for stainless steel and aluminum.

- Efficient Design: Look for a machine with ergonomic designs that optimize operator comfort and minimize downtime.

- Affordability: Search for competitive CNC cutting machine prices. We offer affordable solutions while maintaining elite standards for performance and reliability. Terms like CNC oxyfuel cutting machine price in India are often searched, and at E S HAJI & CO., we aim to offer tailored pricing that adds value.

Maintenance and Safety Tips

Ensuring the longevity of your CNC oxyfuel cutting machine involves regular maintenance and adherence to safety protocols. Here’s what to keep in mind:

Maintenance Tips

- Routine Inspections: Check gas connections, torch alignment, and software functionality regularly.

- Cleaning: Remove slag and debris from cutting surfaces and torches to maintain cutting precision.

- Calibration: Regularly calibrate the CNC system to avoid issues with accuracy.

- Service Schedule: Follow the manufacturer’s recommended servicing interval to keep the machine in pristine condition.

Safety Tips

- Proper Ventilation: Always operate your machine in a well-ventilated area to prevent gas buildup.

- PPE for Operators: Personal protective equipment such as safety goggles, gloves, and flame-resistant clothing is non-negotiable.

- Software Training: Ensure operators are well-trained to handle CNC software and hardware accurately.

- Emergency Protocols: Establish clear guidelines for addressing gas leaks or malfunctioning components.

Why Choose CNC Oxyfuel Cutting Machines from E S HAJI & CO

E S HAJI & CO. stands out as a trusted name among CNC cutting machine manufacturers in India. Here’s why:

- Expert Curation: Our CNC oxyfuel cutting machines are designed for rigorous industrial applications, empowering businesses to deliver quality results.

- State-of-the-Art Technology: Powered by Hypertherm MaxPro200, our machines offer high-performance plasma cutting solutions for stainless steel and aluminum, along with MS cutting capabilities.

- Tailored Solutions: We understand that every industry has unique needs, which is why we provide customized recommendations for your business.

- Exceptional After-Sales Support: From installation to routine maintenance, our team is here to support your investment at every step.

- Unmatched Pricing: Competitive CNC oxy fuel cutting machine price without compromising on the quality and durability that sets E S HAJI & CO. apart.

Investing in a CNC oxyfuel cutting machine from E S HAJI & CO. means you’re choosing efficiency, precision, and reliability. Contact us today to learn more or request a quote.