J-Bolts and L-Bolts: Which Anchor is Right for Your Project?

Construction projects rely on the smallest details to ensure structural integrity. While massive steel beams and concrete foundations get all the glory, the humble anchor bolt is doing the heavy lifting literally. These fasteners are the critical link between structural elements and concrete foundations, preventing movement and ensuring stability.

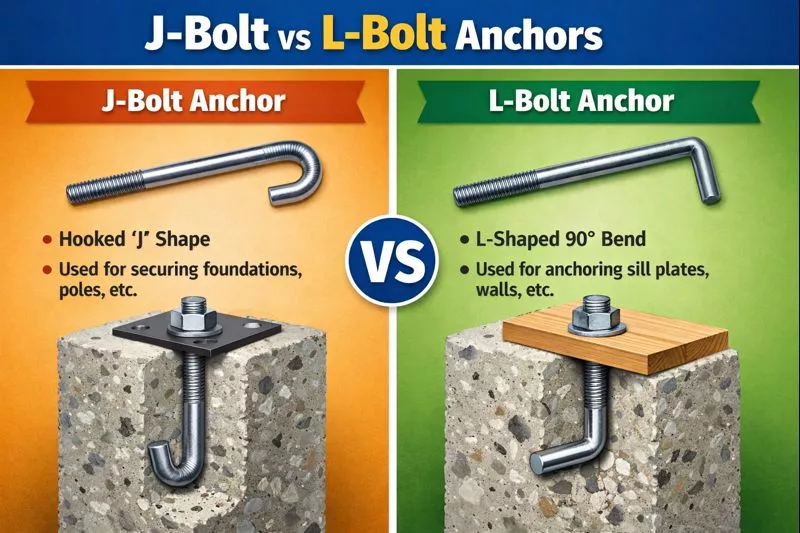

Choosing the right anchor bolt might seem like a minor decision, but it can have major implications for the safety and longevity of a structure. Among the most common types used in the industry are J-bolts and L-bolts. Both are bent-bar anchors, designed to be embedded in wet concrete, but they serve different purposes and have distinct characteristics.

If you are a contractor, engineer, or DIY enthusiast, understanding the nuances between these two fasteners is essential. In this guide, we break down the specific features, load capacities and ideal applications for both J-bolts and L-bolts to help you make the right choice for your next build.

What is a J-Bolt?

As the name suggests, a J-bolt is shaped like the letter “J.” It consists of a threaded end on top for attaching nuts and washers and a curved, hook-like bottom that gets embedded into concrete.

Key Characteristics

The defining feature of a J-bolt is the hook. When concrete cures around this bent section, the unique shape provides substantial resistance against being pulled out. The hook acts as an anchor mechanism, leveraging the weight and strength of the hardened concrete to hold the bolt in place.

These bolts are typically made from stainless steel, galvanized steel, or plain carbon steel, depending on the environmental requirements of the project. They come in various diameters and lengths, allowing them to be tailored to specific load requirements.

What is an L-Bolt?

Similarly named for its shape, the L-bolt resembles the letter “L.” It features a vertical threaded section and a horizontal “leg” at the bottom bent at a 90-degree angle.

Key Characteristics

The 90-degree bend is the L-bolt’s primary anchoring mechanism. Like the hook of the J-bolt, this horizontal leg is embedded in wet concrete. Once the concrete sets, the leg creates resistance against uplift and tension forces.

L-bolts are often used in similar materials to J-bolts typically steel or stainless steel and are usually threaded on the top end to accept a nut and washer. They are a standard in many light-to-medium duty construction applications.

Comparing J-Bolts and L-Bolts

While they look somewhat similar and are installed in much the same way, the differences between these two anchors become apparent when we look at their performance and application.

Load Capacity and Pull-Out Strength

The primary distinction lies in how they handle tension. Because of its hooked shape, the J-bolt often provides superior pull-out resistance compared to the L-bolt in certain configurations. The hook engages more surface area of the concrete in a way that makes it difficult to extract vertically.

However, L-bolts are excellent at preventing rotation. The 90-degree leg locks the bolt into the concrete, ensuring that the bolt does not turn when a nut is tightened on the exposed threaded end. This is a critical feature during the installation of wall plates or machinery.

Installation Process

Both bolts are “cast-in-place” anchors. This means they must be positioned precisely before the concrete is poured.

- Positioning: The bolts are often tied to the rebar grid or held in place by a template to ensuring they stay upright and in the correct location.

- Pouring: Concrete is poured around them.

- Curing: Once the concrete cures, the bolt is permanently fixed.

The installation difficulty is roughly the same for both. The challenge lies in ensuring they remain vertical and don’t sink or float during the pour.

Applications

- J-Bolts: Frequently used in heavier construction where high tensile strength is required. They are common in securing heavy machinery, structural steel columns and roofing structures where uplift from wind is a concern.

- L-Bolts: The standard choice for securing wood sill plates to concrete foundations in residential construction. If you walk onto a home building site, you will likely see L-bolts protruding from the foundation walls, ready to accept the wooden framing. They are also widely used for light posts and sign poles.

Pros and Cons of J-Bolts

Advantages:

- High Pull-Out Resistance: The hook shape offers excellent grip within the concrete.

- Versatility: Suitable for a wide range of heavy-duty applications.

- Durability: When made from the right materials, they can withstand significant stress.

Disadvantages:

- Placement Precision: Because of the hook, it can sometimes be trickier to navigate the bolt through dense rebar cages during setup compared to the straighter profile of an L-bolt.

Pros and Cons of L-Bolts

Advantages:

- Anti-Rotation: The 90-degree bend prevents the bolt from turning when you tighten the nut, which speeds up construction.

- Cost-Effective: Often simpler to manufacture and readily available for residential needs.

- Standardization: They are the go-to standard for many residential codes regarding sill plate attachment.

Disadvantages:

- Lower Pull-Out Resistance: In some high-tension scenarios, the simple 90-degree bend may offer less resistance to uplift than a hooked J-bolt.

Real-World Examples of J-Bolts and L-Bolts

To better understand where these bolts fit in, let’s look at two hypothetical scenarios:

Project A: Residential Garage

A contractor is framing a new detached garage. They need to secure the wooden sill plate (the bottom piece of the wall frame) to the poured concrete slab. Here, the contractor chooses L-bolts. The anti-rotation feature makes it easy to tighten the nuts down on the sill plate quickly and the load requirements for a single-story garage are well within the L-bolt’s capabilities.

Project B: Cell Tower Base

An engineering team is designing the foundation for a new cell tower. The structure is tall and subject to high wind loads, creating significant uplift forces on the base. In this case, the engineers might specify heavy-duty J-bolts (or even headed anchor bolts). The hooked design provides the necessary insurance that the bolts will not pull out of the concrete foundation during a storm.

Factors to Consider When Choosing J-Bolts and L-Bolts

Selecting the right anchor isn’t just a matter of preference; it’s a matter of physics and code compliance.

- Load Requirements: Calculate the tension (pull-out) and shear (sideways) forces the bolt must withstand. Heavier loads generally require J-bolts or specialized headed bolts.

- Building Codes: Local building codes often dictate the diameter, length and type of bolt required for specific connections, particularly in seismic or high-wind areas.

- Embedment Depth: How deep into the concrete does the bolt need to go? Deeper embedment usually offers better hold.

- Material: Stainless steel is best for corrosive environments, while galvanized is suitable for exterior use. Plain steel is fine for interior, dry applications.

At E S HAJI & CO., we understand that sourcing the right fastener is critical to your project’s success. Whether you need standard L-bolts for residential framing or custom J-bolts for specialized industrial applications, the quality of the steel and the precision of the bend matter.

Final Thoughts on Anchor Selection for J-Bolts and L-Bolts

While J-bolts and L-bolts share a similar function anchoring structures to concrete their differences dictate their use. L-bolts are the champions of residential sill plates and light poles, valued for their anti-rotation properties and ease of use. J-bolts step in when higher pull-out resistance is needed, securing heavy machinery and structural steel elements.

Consulting with a structural engineer is always the safest route to determine which bolt fits your specific load requirements. Once you know what you need, ensure you source your anchors from a reputable supplier like E S HAJI & CO. to guarantee material quality and reliability.

J-Bolts and L-Bolts

Discover the essential distinctions between J-bolts and L-bolts, including their design, load capacity, and installation processes. Learn which anchor is best suited for your construction projects to ensure safety, durability, and optimal performance.

Product Brand: E S HAJI & CO.

Product Currency: INR

Product In-Stock: InStock

5