Choosing the Right Custom Flange for Oil and Gas Applications

Flanges are a critical component in the oil and gas industry, ensuring the safe and efficient transfer of liquids and gases across complex pipeline systems. While standard flanges can meet the needs of many applications, custom flanges are often necessary for unique and demanding environments. But how do you choose the right custom flange for your operations? This guide dives into the essential factors to consider, ensuring you make informed decisions that enhance performance and compliance.

Whether you’re working with high-pressure systems or corrosive environments, this guide will walk you through material selection, design considerations, regulatory compliance, and more. By understanding these critical aspects, you can achieve reliability and efficiency in one of the world’s most demanding industries.

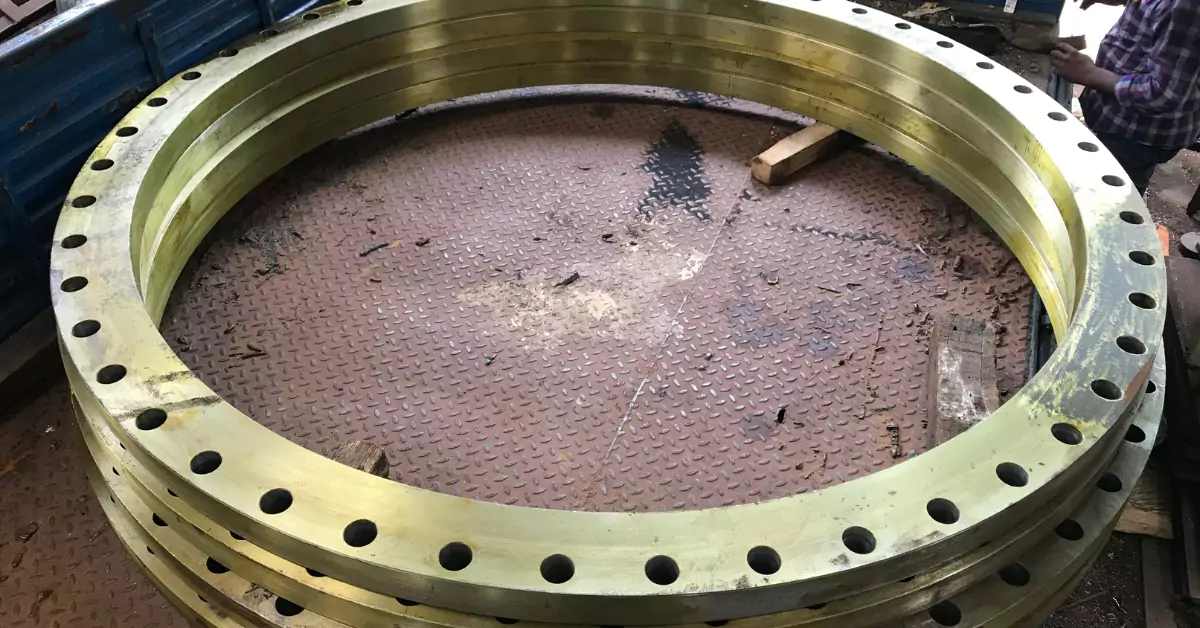

Introduction to Custom Flanges in Oil and Gas

Custom flanges are specifically designed and manufactured to meet the unique requirements of specific projects or systems in the oil and gas sector. Unlike standard flanges, which come in predefined sizes and materials, custom flanges offer a tailored solution for complex challenges. Whether for offshore rigs, refineries, or subsea gas fields, their role in minimizing leaks, ensuring safety, and maintaining structural integrity cannot be overstated.

Why Choose Custom Flanges?

- Unmatched fit for unique designs and setups.

- Improved durability for extreme environments.

- Greater reliability in high-pressure or corrosive applications.

E S HAJI & CO., one of the leading flange manufacturers in Chennai, specializes in crafting high-quality custom flanges for a variety of oil and gas applications. Working with trusted manufacturers like E S HAJI & CO. ensures you receive components designed with precision and care.

Understanding Critical Requirements

Custom flanges must adhere to specific operational demands. Before you even begin the design process, it’s vital to consider the system’s conditions, including:

- Pressure and Temperature Tolerance: Oil and gas pipelines often operate under high-pressure conditions ranging from 150 PSI to over 2500 PSI. The flange must be designed to withstand these pressures while accommodating temperatures that vary from sub-zero in Arctic regions to extreme heat in desert environments.

- Corrosion Resistance: Many oil and gas applications involve transporting corrosive fluids or gases, which can damage standard materials over time. Choosing the wrong flange can lead to costly maintenance or catastrophic failures.

- Application Type: Consider whether the flange will be used in offshore wind platforms, subsea pipelines, onshore refineries, or mobile drilling units. Each environment presents unique requirements.

Material Selection Criteria

Material selection is one of the most critical decisions in flange manufacturing. Ensuring compatibility with the operating environment boosts longevity and performance. Here are factors to guide your choice:

- Material Types

- Carbon Steel: Best suited for high-pressure but non-corrosive applications.

- Stainless Steel (e.g., 304/L or 316/316L): Offers higher corrosion resistance and is ideal for marine or acidic environments.

- Duplex Stainless Steel: A balanced option suitable for high-strength and corrosion-resistant requirements.

- Nickel Alloys like Monel and Hastelloy: Resist extreme corrosion in challenging chemical environments.

- Alignment with Fluids

You’ll need to determine the types of materials being transported, whether crude oil, natural gas, or chemically treated products. A material resistant to these specific agents ensures the flange’s durability.

- Environmental Impact

Offshore and subsea applications particularly demand corrosion-proof materials due to constant exposure to saltwater. Choose materials with robust anti-corrosion properties for such settings.

Design Considerations for High-Pressure Systems

Effective flange design lies at the intersection of engineering and application needs. Tailoring the flange involves calculations for pressure ratings, bolt type, and interface compatibility.

1. Pressure Ratings and Dimensions

Ensure the flange meets the relevant ASME or ANSI pressure ratings. For high-pressure systems, ratings like Class 1500 or Class 2500 are typically necessary to avoid flange deformation or leakage over time. Flange dimensions should also align perfectly with pipe specifications to ensure proper assembly.

2. Sealing Mechanisms

High-pressure systems benefit from gaskets and seals that prevent leaks, even during fluctuations in pressure or temperature. Choose sealing elements compatible with your selected flange materials and operating conditions. Spiral-wound gaskets or RTJ gaskets are common choices for extreme pressures.

3. Bolt Patterns and Strength

To evenly distribute stress, bolt patterns should adhere to internationally recognized standards (e.g., ASME B16.5). Bolts themselves must withstand both the clamping force and operational stress changes.

Regulatory Compliance and Standards

Compliance with international standards ensures the quality and safety of custom flanges in oil and gas settings. Here are the most critical you should consider:

- ASME B16.5 & ASME B16.47 for pressure and size ratings.

- API 6A for wellhead and Christmas tree equipment.

- ISO 9001 certified manufacturers guarantee high-quality production.

Manufacturers like E S HAJI & CO., established flange manufacturers in Chennai, adhere to these stringent guidelines, making them a trusted name in the industry.

Expert Recommendations to Get Started

Choosing the right custom flange is pivotal for safety, efficiency, and cost savings in oil and gas operations. Partnering with reliable manufacturers like E S HAJI & CO., renowned custom flange manufacturers in Chennai, ensures high-quality, compliant, and durable components.

For your next oil and gas project, evaluate operational requirements, consult with experts, and consider investing in advanced materials for long-term benefits. Reach out to manufacturers like E S HAJI & CO. to discuss your custom flange needs and elevate your operation’s performance.

Flanges

Discover the key factors for choosing custom flanges tailored to oil and gas applications. Learn about material durability, optimal design, industry compliance, and sourcing from reputable manufacturers like E S HAJI & CO. Ensure your projects meet performance standards and enhance operational efficiency.

Product Brand: E S HAJI And CO

Product Currency: INR

Product In-Stock: InStock

5