Sheet Metal Fabrication: Techniques & Best Practices at Scale

Sheet metal fabrication is the backbone of many industries, from automotive and aerospace to construction and consumer electronics. Whether you’re crafting intricate sheet metal parts or scaling production for large manufacturing runs, understanding the techniques and best practices in this field is crucial to achieving efficiency and high-quality output.

we’ll explore the key techniques behind sheet metal fabrication, best practices for scaling production, and emerging technologies shaping the industry. By the end, you’ll have actionable insights into how sheet metal fabrication processes can drive your operations forward.

What is Sheet Metal Fabrication?

Sheet metal fabrication refers to the process of forming flat sheets of metal into specific shapes or products through cutting, bending, assembling, and other techniques. It plays a pivotal role in producing everything from simple brackets to complex machinery components, offering durability, precision, and customization.

Common Materials in Sheet Metal Fabrication

The versatility of sheet metal fabrication stems from the range of materials used. Each metal offers unique advantages, depending on the application. The most commonly used sheet metals include:

- Aluminum: Lightweight, corrosion-resistant, and ideal for industries like automotive and aerospace.

- Steel: Known for its strength and affordability; stainless steel is especially valued for its corrosion resistance.

- Copper: Highly conductive and often used in electrical applications.

- Brass: A durable yet aesthetically pleasing metal, commonly used in decorative designs or mechanisms requiring low friction.

These materials form the foundation of every process within the sheet metal fabrication industry.

Key Fabrication Techniques

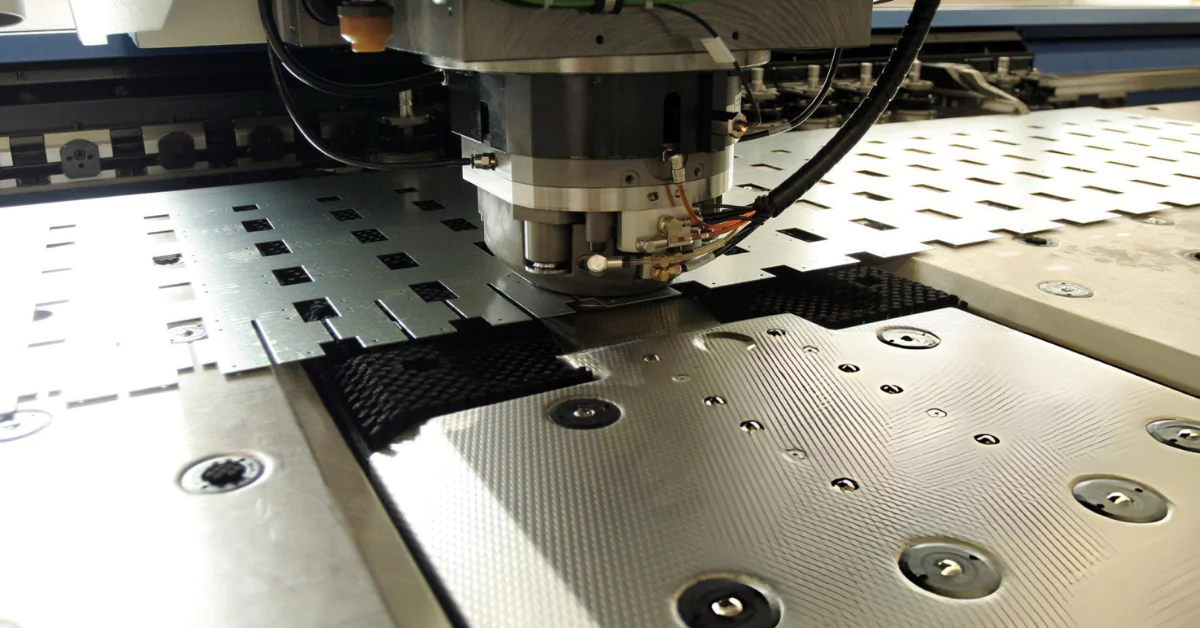

Cutting

The first step in most sheet metal fabrication processes involves cutting the metal sheet into the desired sizes and shapes. Precision is critical, and the industry offers various cutting techniques:

- Laser Cutting: Suitable for clean, precise cuts with minimal waste. Ideal for detailed designs.

- Plasma Cutting: Faster than laser cutting and effective for thicker sheets, though less precise.

- Waterjet Cutting: Uses high-pressure water mixed with abrasives to cut through metals without generating heat, making it perfect for temperature-sensitive materials.

Forming

Forming is where the flat sheet takes shape through bending, stamping, or rolling. The choice of method depends on the complexity of the design and production requirements.

- Bending: Using press brakes or roll bending machines to create precise angles in the sheet metal.

- Stamping: A high-speed process for producing large volumes of identical parts by pressing the metal between dies.

- Rolling: Forms curved or cylindrical shapes, commonly used in piping and ducting.

Joining

Once the parts are cut and formed, they are joined to create the final product. Common joining techniques include:

- Welding: Provides strong, permanent bonds between metal parts. MIG, TIG, and spot welding are popular in sheet metal fabrication.

- Riveting: A non-permanent method of connecting parts, often used in industries like construction and aviation.

- Adhesives: Used when welding or riveting might alter the material properties, such as in lightweight applications.

Best Practices for Scalability

Scaling up sheet metal fabrication requires more than just investing in machinery. It’s about designing efficiently, fine-tuning processes, and maintaining consistent quality.

Design Considerations for Manufacturability

Efficient design is the foundation of scalable fabrication. Engineers should prioritize designs that simplify fabrication and minimize material waste. For instance:

- Use fewer, universal parts that reduce the complexity of assembly.

- Stick to standard material sizes and thicknesses to reduce custom machining needs.

- Incorporate clear tolerances to ensure ease of manufacturing.

Optimizing Processes for High-Volume Production

High-volume production demands robust process optimization:

- Automated Machining: Machines like CNC laser cutters and press brakes can handle repetitive tasks with consistent precision.

- Efficient Material Handling: Automated material feeders and robotic handlers streamline workflows.

- Lean Manufacturing Principles: Eliminate unnecessary steps, reduce downtime, and continuously monitor workflows to enhance throughput.

Quality Control and Inspection Methods

Maintaining high standards across scaled-up production can be challenging. Quality control should include:

- Regular inspections using non-destructive methods like ultrasonic or x-ray testing.

- Implementing Statistical Process Control (SPC) to detect deviations from production norms.

- Post-production testing, such as tensile strength tests, to verify the durability of sheet metal parts.

Advanced Techniques and Technologies

The adoption of advanced technologies is reshaping the possibilities within the sheet metal fabrication industry.

Automation in Sheet Metal Fabrication

Automation plays a key role in scaling operations. Robotic arm systems can handle complex welding or bending tasks, significantly reducing human error and accelerating production times.

Use of CAD/CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are crucial for modern fabrication. They allow designers to create highly efficient, precise designs that can be directly implemented into automated machinery.

Integration with Other Manufacturing Processes

Fabrication does not exist in isolation; it must integrate with other production processes:

- Additive Manufacturing (3D Printing): Combines with sheet metal to create hybrid designs.

- Surface Finishing Processes like powder coating improve the durability and aesthetic appeal of the final product.

What’s Ahead for Sheet Metal Fabrication?

The future of sheet metal fabrication will undoubtedly focus on smarter automation, more sustainable materials, and enhanced efficiency. Companies like E S HAJI & CO. are already leveraging cutting-edge techniques to meet global demands. For businesses looking to streamline their operations or individuals searching for “sheet metal fabrication near me,” keeping track of these trends can provide a significant competitive advantage.

Whether it’s exploring different types of sheet metal fabrication, creating specialized sheet metal fabrication products, or downloading resources like a sheet metal fabrication PDF, the key to success lies in continuous learning and innovation.