Why Slip-On Flanges Are a Top Choice in the Industry

E S HAJI & CO, specialists in MS and Flange Supplier in Chennai, uphold strict quality control with accredited inspections, ensuring top-quality products. Their commitment to excellence and timely deliveries has earned them a reputation for customer satisfaction. In this blog, E S HAJI & CO highlights the popularity of Slip-On Flanges in the industry. Their ease of installation, versatility, and ability to accommodate various pipe sizes make them ideal for industrial use. The design enhances safety by providing a secure, leak-resistant connection, making them a reliable choice for high-pressure applications across various sectors.

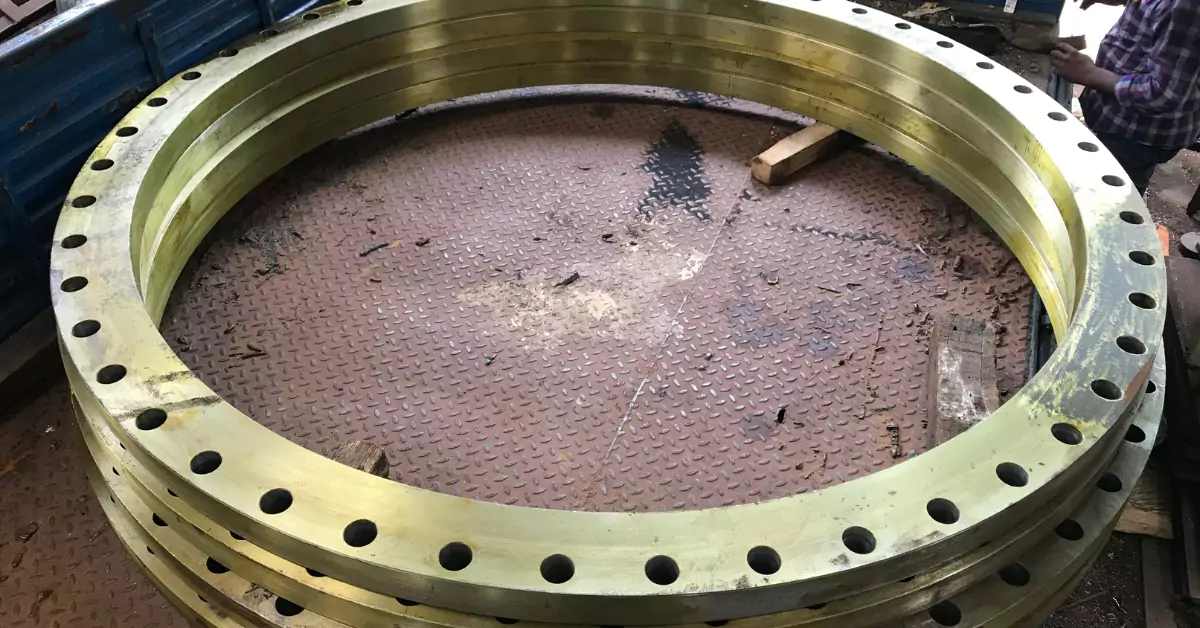

Understanding the Design and Functionality of Slip-On Flanges

Slip-on flanges are engineered to slide over a pipe and are welded both internally and externally to ensure structural strength and prevent leakage. The process begins with the pipe end being cut square, and the flange bolt holes are aligned in a plane perpendicular to this surface on a square bearing face. A fillet weld is applied at the end of the pipe to connect it to the inside of the flange bore, while another fillet weld is made around the back end of the flange hub to secure it to the exterior of the pipe. After achieving proper alignment with temporary tack welds, final welding is completed. Slip-on flanges are generally more cost-effective than weld-neck flanges, which contributes to their popularity among buyers.

How Slip-On Flanges Provide Cost-Effective Solutions

However, the initial cost savings can be offset by the added expense of the two fillet welds required for a secure installation. Despite their lower cost, slip-on flanges might not offer the same level of durability as weld-neck flanges, which are designed to handle higher stress and provide greater longevity under demanding conditions. For specific applications, there are also socket-type slip-on flanges, which require welding only on the outside. These socket-type flanges provide an alternative for situations where welding access is limited to the flange’s exterior, offering a solution tailored to particular installation requirements.

When to Use a Slip-On Flange: Key Applications

What is the best time to use a slip-on Flange Thanks to their versatility and efficiency these flanges are among the most popular types of flanges used in the market. For lower pressure applications, they are ideal making them common among various piping systems. One advantage of slip-on flanges is that you don’t need to specify a pipe schedule when using them. This is because the inside diameter of the Flange Dealers in Chennai is dependent upon the outside one of the pipe which remains constant throughout different pipe schedules. Stocking is simplified for vendors due to this uniformity and helps fabricators since it’s slightly easier aligning these flanges compared to weld neck ones. Besides, cutting the pipe right length also becomes much clearer when using slip on flanges.

Advantages of Slip-On Flanges in Lower Pressure Systems

In many cases where welding necks would have been used, slip on flanges have become more preferred because they are cheaper and do not need high precision when cutting the pipes. While slip-on flanges can be used in high temperatures and pressures; nevertheless, unlike other types of flanges, they are generally not recommended for such conditions. According to ASME B16.5 Code; nonetheless, Slip-On Flanges use is limited for weight classes 1500#-2500#. E S HAJI & CO offers Slip-On Flanges made out of stainless steel as well as carbon steel materials catered towards diverse industrial

Key Features of Slip-On Flanges by E S HAJI & CO

Versatile Sizing: Slip-On Flanges are the most commonly stocked type of flange because they fit all pipe schedules. Their design allows them to accommodate the outside diameter of the pipe, simplifying inventory and making them a go-to option for many applications.

Versatile Sizing and Easy Fabrication

Ease of Fabrication: These flanges make it easier for fabricators to cut pipes to the correct length. Their smaller thickness also facilitates easier alignment of bolting holes, streamlining the installation process.

Limitations and Application Guidelines According to ASME B16.5

Application Limitations: According to the ASME B16.5 code, Slip-On Flanges are restricted to use in 1500#-2500# weight classes. They are generally not recommended for high-pressure or high-temperature environments due to their limitations compared to other flange types.

Slip-On Flanges

Discover the advantages and key features of Slip-On Flanges with E S HAJI & CO, Chennai's leading custom flange manufacturer.

Product Brand: ES HAJI & CO

Product Currency: INR

Product Price: 100

Price Valid Until: 2024-12-31

Product In-Stock: InStock

5