Introduction to CNC Turning

CNC Turning is a highly advanced manufacturing technique used to create precise, cylindrical parts with exact specifications. As one of the core processes in the CNC machining world, it is essential for industries ranging from automotive to aerospace. In this blog, we will delve into the details of CNC Turning, its process, and how it is used to produce high-quality parts.

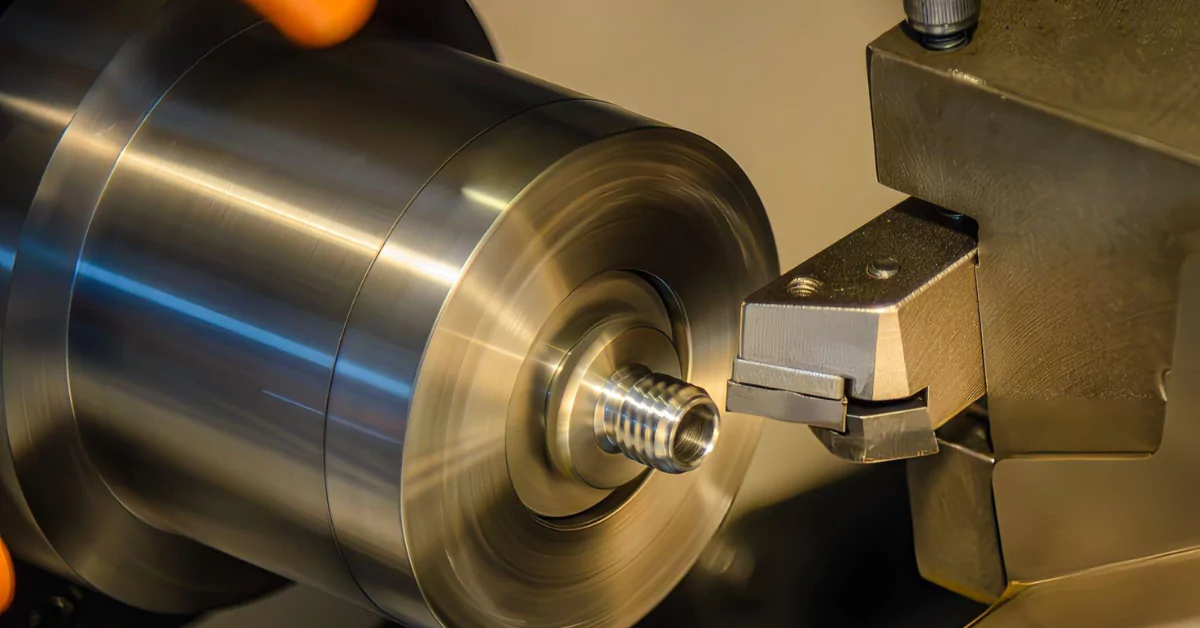

CNC Turning refers to the process where a rotating CNC turning machine or CNC turning lathe is used to remove material from a workpiece, creating the desired shape and size. This process allows for high precision and the ability to work with a variety of materials such as metals, plastics, and wood. Unlike traditional manual lathes, CNC lathes are operated using computer-controlled programs, ensuring consistent and accurate results every time.

CNC Turning vs. Milling: Key Differences

While CNC turning and CNC milling both fall under the umbrella of computer numerical control machining, they have distinct differences. Turning is primarily used for creating cylindrical or round parts, while milling is ideal for shaping flat surfaces and creating holes or slots. The fundamental difference between the two lies in how the workpiece is held and manipulated. In CNC turning, the workpiece rotates, and the tool moves along it, whereas, in CNC milling, the tool rotates while the workpiece remains stationary.

CNC Turning Process Explained

The CNC turning process begins by setting up the workpiece on the turning center machine. The machine rotates the piece, while a cutting tool is applied to remove material. The computer program (often a CNC turning program) controls the movement of the tool, ensuring that the part meets the precise measurements required. There are various types of CNC turning operations, including straight turning, taper turning, and threading, depending on the complexity of the part.

CNC Turning Machines and Their Components

CNC Turning Machines and Their Components

A CNC turning lathe machine consists of several components that work in tandem to ensure smooth operation. These include the spindle, tool turret, tailstock, and CNC control panel. The spindle holds and rotates the workpiece, while the tool turret contains multiple cutting tools that can be swapped in and out automatically. The tailstock is used for supporting longer workpieces, and the CNC control panel allows the operator to input the program and monitor the machine’s operation.

Types of CNC Turning Machines

There are several types of CNC turning centers available for different types of work. These machines include the CNC turning lathe, CNC turn mill machine, and CNC turning and milling machine. The CNC turning lathe machine is designed specifically for turning operations, while the CNC turn mill machine combines turning and milling capabilities for more complex parts. The CNC turning and milling machine allows for both operations to be performed in a single setup, increasing efficiency and reducing cycle time.

Applications of CNC Turning

CNC turning is widely used in the manufacturing of precision parts. Some of the most common applications include:

- Aerospace parts – CNC turning is essential in creating lightweight yet durable parts for the aerospace industry.

- Automotive components – Parts like engine components, shafts, and gears are commonly manufactured using CNC turning.

- Medical devices – CNC turning is used to create highly precise medical components such as implants and surgical instruments.

- Electronics – The production of small, complex parts for electronic devices is made possible through CNC turning.

CNC Turning Services

CNC Turning Services

CNC turning services are offered by manufacturers who specialize in precision machining. These services are essential for companies that require high-quality, custom-made parts. Working with a trusted CNC turning manufacturer like E S HAJI & CO. ensures that each part is crafted with the utmost attention to detail, using advanced CNC turning tools and the latest technology. Whether you need standard CNC turning machining services or custom solutions, professional services can provide the exact specifications and tolerances you require.

Benefits of CNC Turning

The benefits of CNC turning include:

- Precision and Accuracy – CNC machines are capable of producing parts with incredible precision, ensuring a high level of consistency.

- Versatility – CNC turning can be used to machine a wide variety of materials, making it suitable for numerous industries.

- Efficiency – Automated processes reduce the time required for production, allowing for faster turnaround times.

- Cost-effectiveness – While the initial setup cost for CNC machines may be high, the long-term benefits of reduced labor costs and high-quality production make it a cost-effective choice.

In conclusion, CNC turning is a fundamental process in modern manufacturing, providing precision and efficiency for producing cylindrical parts. Whether you’re dealing with CNC turning lathe machines, CNC turning centers, or CNC turn mill machines, the versatility of this technology makes it essential in numerous industries, including aerospace, automotive, and medical fields. With companies like E S HAJI & CO., you can be assured of top-notch CNC turning services that meet your exact specifications.