A Comprehensive Guide to Laser Cutting Technology

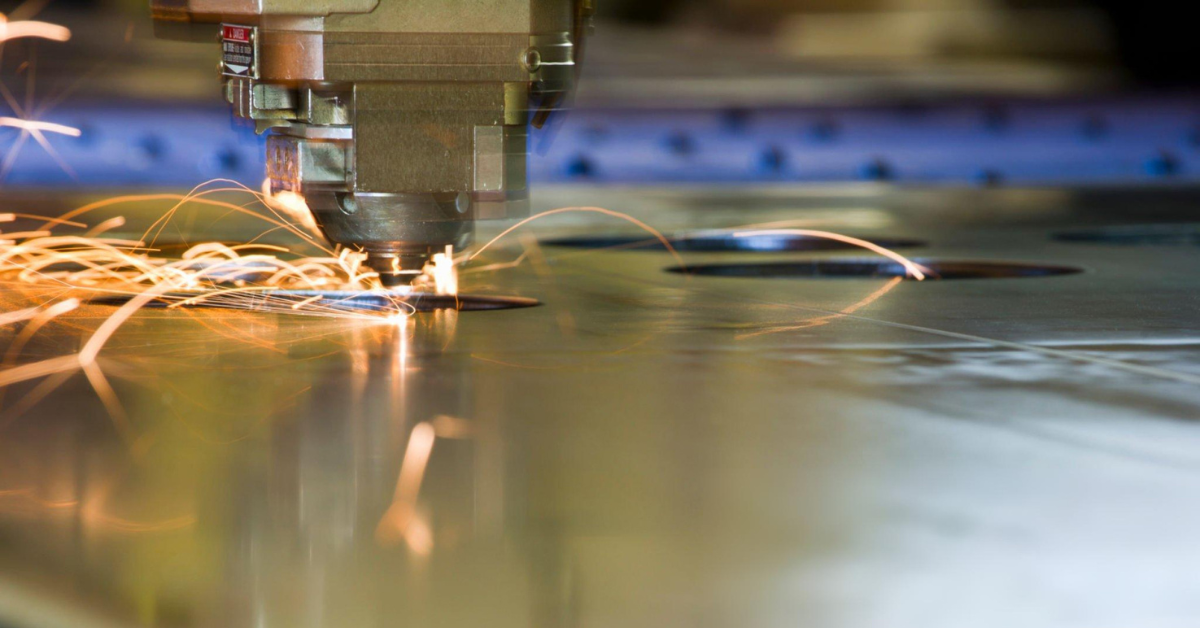

Laser cutting is a precision-based manufacturing process used to cut or engrave various materials with the help of a focused laser beam. It has become an essential technology in industries like automotive, architecture, fabrication, and interior design due to its high accuracy, speed, and versatility. Companies like E S HAJI & CO. specialize in providing Laser Cutting services for a wide range of applications.

Understanding Laser Cutting Design

Laser cutting design refers to the digital blueprints or patterns created to guide the laser cutter in cutting various materials. These designs are created using software and are often used in metal laser cutting design, CNC laser cutting design, and other applications. Laser cutters follow these patterns with high precision to produce intricate shapes, reducing the need for additional finishing work.

For example, in laser cutting gate design, a digital design can be created to cut complex patterns into gates, ensuring a perfect, customized result. Whether for laser cutting sheet metal or laser cutting steel sheet, the design is a crucial step in achieving a high-quality final product.

Types of Laser Cutting Machines

Types of Laser Cutting Machines

There are two main types of laser cutting machines widely used in the industry:

- CO2 Laser Cutting Machine: Ideal for cutting non-metal materials like wood, acrylic, and plastic, CO2 laser cutting machines use carbon dioxide as a laser medium.

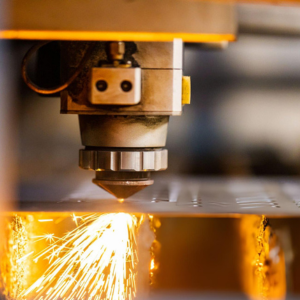

- Fiber Laser Cutting Machine: These machines are used primarily for cutting metals like steel, stainless steel, and other alloys. Fiber lasers provide superior precision and speed compared to CO2 lasers, making them ideal for laser cutting for metal and metal sheet laser cutting applications.

Laser Cutting Applications

Laser cutting is used in various industries, each benefiting from its unique properties like precision, speed, and ability to cut complex shapes.

- Laser Cutting for Metal: One of the most popular uses of laser cutting is laser cutting for metal. Whether it’s cutting stainless steel, iron gate design, or steel laser cutting design, laser technology allows for precise cuts that traditional cutting methods cannot achieve. This makes it ideal for laser cutting for sheet metal fabrication and laser cutting for automotive parts.

- Laser Cutting for Custom Designs: Laser cutting for custom designs allows for the creation of unique and personalized pieces. From intricate laser cutting pattern design to laser cutting for custom gates and laser cutting door design, this flexibility has made laser cutting an integral part of interior design, architecture, and fabrication.

- Laser Cutting for Industrial Applications: Laser cutting for industrial applications covers a broad spectrum of uses. For example, laser cutting MS sheet is commonly employed in the manufacturing of industrial components. Additionally, laser cutting for product design enables manufacturers to create innovative and precise products at scale.

Advantages of Laser Cutting

The primary reasons why laser cutting has become so popular in industrial settings are:

- High Precision: Laser cutting is known for its accuracy and ability to cut complex shapes without the need for additional machining. This makes it ideal for applications like laser cutting engraving and laser cutting precision.

- Clean Edges: The use of laser allows for clean, smooth edges that require minimal finishing, whether in laser cutting acrylic design or laser cutting steel gate production.

- Flexibility: Whether you’re working with wood laser cutting design or laser cutting for metal sheets, laser cutting offers great flexibility in terms of materials and applications.

- Cost-Effective: Though the initial setup cost of a laser cutting machine may seem high, the long-term benefits—such as faster production times, reduced material wastage, and no need for tool changes—make it a cost-effective solution for many businesses.

Laser Cutting Machine Price and Working Principle

The laser cutting machine price varies depending on the type of machine and its capabilities. For instance, a fiber laser cutting machine generally costs more than a CO2 laser cutting machine due to its higher performance and precision.

Understanding the laser cutting machine working principle is crucial for businesses that want to invest in this technology. The laser beam focuses on the material, which melts or vaporizes, leaving behind the desired cut. The speed and power of the laser are controlled precisely to ensure accuracy and efficiency in cutting various materials, from metals like steel and stainless steel to non-metals like acrylic and wood.

Industries Benefiting from Laser Cutting

Industries Benefiting from Laser Cutting

Laser cutting has widespread applications in various industries:

- Automotive: From laser cutting for automotive parts to metal laser cutting design, this technology is used extensively to produce car parts with tight tolerances.

- Signage: Laser cutting for signage allows businesses to create eye-catching, precise signs using materials like acrylic, stainless steel, or aluminum.

- Fabrication: Laser cutting for fabrication is one of the most common applications, with industries relying on laser cutting to produce intricate designs in metal sheets and other materials.

- Interior Design: Laser cutting for interior design and laser cutting for home décor is increasingly popular, as it enables designers to create unique, personalized pieces for modern spaces.

The Future of Laser Cutting

As the technology behind laser cutting continues to evolve, its potential for innovation and customization is vast. Whether you’re looking for laser cutting for stainless steel, laser cutting engraving, or laser cutting for custom designs, it’s clear that laser cutting offers exceptional versatility across various industries. For businesses looking for precision, speed, and flexibility, laser cutting is an ideal solution.

At E S HAJI & CO., we offer cutting-edge laser cutting services for all your industrial and custom needs. Whether you need laser cutting for metal sheets or CNC cutting for architectural designs, our advanced machines and expert team ensure top-quality results.

Laser Cutting

Explore E S HAJI & CO.'s state-of-the-art Laser Cutting services for your industrial and design needs. Our CO2 laser cutting machine and fiber laser cutting machine provide precise, clean cuts for materials like steel, stainless steel, acrylic, and wood. Whether you need laser cutting for custom gates, laser cutting for sheet metal fabrication, or laser cutting for signage, we deliver high-quality results with precision and efficiency.

Product Brand: E S HAJI And CO

Product Currency: INR

Product In-Stock: InStock

5