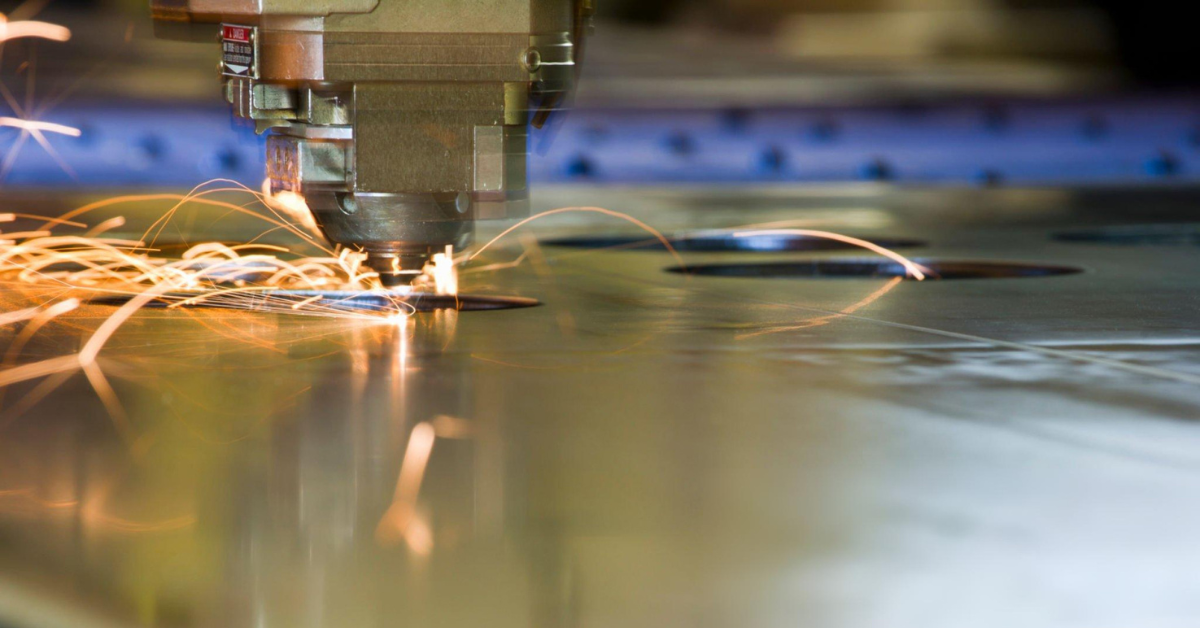

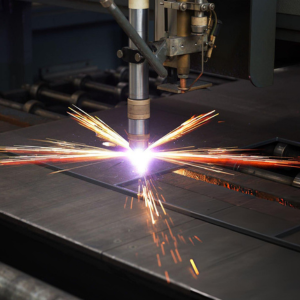

Understanding the Process and Benefits of Plasma Cutting

Plasma cutting is a highly efficient process used for cutting various types of metals, including steel, aluminum, and stainless steel. It utilizes a plasma torch to melt and remove material, offering precision and speed in the cutting process. Unlike traditional methods like oxy-fuel cutting, plasma cutting is ideal for projects requiring intricate designs and high-speed performance. In this article, we’ll explore the plasma cutting process, its applications, and how it compares with other methods like laser cutting.

Plasma Cutting Process: How Does It Work?

The plasma cutting process involves using a high-velocity jet of ionized gas (plasma) to cut through metal. The gas is electrically charged, creating a plasma arc that melts the metal at the cutting point. The plasma cutting torch directs this ionized gas onto the metal, melting it and blowing the molten material away. The result is a precise cut with minimal distortion.

Plasma Cutting Machine Working Principle

A plasma cutting machine consists of a power supply, a plasma cutting torch, and a plasma cutting nozzle. The torch creates the plasma arc, and the nozzle controls the flow and direction of the gas. Different gases, such as oxygen, nitrogen, or compressed air, are used depending on the material being cut.

Plasma Cutting vs Laser Cutting: Which is Better?

Plasma Cutting vs Laser Cutting: Which is Better?

Both plasma cutting and laser cutting are effective methods for cutting metals, but they have distinct differences. Plasma cutting uses a plasma arc, while laser cutting uses a focused beam of light. The key advantages of plasma cutting include its ability to cut through thicker materials and its versatility in cutting a wide range of metals. However, laser cutting offers finer precision and is ideal for cutting thinner materials. When choosing between the two, it’s important to consider the material thickness, required precision, and the specific needs of the project.

Applications of Plasma Cutting

Plasma cutting is used in a wide variety of industries for different purposes. Some common applications include:

- Metal fabrication: Cutting large sheets of metal for industrial applications.

- Automotive industry: Precision cuts for automotive parts and components.

- Signage: Custom plasma cutting designs for signs and logos.

- Construction and architecture: Creating detailed metal gates and panels using plasma cutting gate design.

Whether it’s plasma cutting for architecture or creating custom designs, plasma cutting proves to be a valuable tool in many sectors.

Plasma Cutting Machine Types and Pricing

There are various types of plasma cutting machines available, each suited to specific tasks:

- Air plasma cutting machines: Ideal for cutting thinner metals with precision.

- Portable plasma cutting machines: Compact and lightweight for easy mobility.

- CNC plasma cutting machines: These machines use computer numerical control for automatic cutting, ensuring high precision and reduced human error.

The plasma cutting machine price can vary based on factors like size, features, and brand. Generally, prices range from a few thousand to tens of thousands of dollars, depending on whether it’s a hand plasma cutting machine or an advanced CNC plasma cutting machine. For those in India, plasma cutting machine price India can differ based on the manufacturer and specifications. Leading brands such as ESAB plasma cutting machine and Hypertherm plasma cutting machine offer high-quality equipment at varying price points.

Advantages of Plasma Cutting

There are several benefits to using plasma cutting over traditional methods like oxy-fuel cutting or laser cutting:

- Faster cutting speed: Plasma cutting can cut through metals much faster than other methods.

- Cost-effective: Plasma cutting machine price is typically lower than that of a laser cutter, making it an affordable option for many industries.

- Versatility: It works on a wide range of metals, including carbon steel, stainless steel, aluminum, and copper.

- Precision: Modern CNC plasma cutting machines ensure accurate cuts with minimal material waste.

For applications like metal cutting and sheet metal fabrication, plasma cutting stands out due to its speed and cost-effectiveness.

Key Components of Plasma Cutting

Key Components of Plasma Cutting

Several components are essential for the plasma cutting process, including the plasma cutting torch, plasma cutting nozzle, and plasma cutting gas. The torch generates the plasma arc, the nozzle controls the gas flow, and the gas serves to ionize and form the plasma. Each component must be carefully maintained to ensure optimal cutting performance.

Choosing the Right Plasma Cutting Machine for Your Needs

- Material type and thickness: Different machines are suited for various materials, with some machines designed for thin metals and others for thicker plates.

- Cutting speed: Higher-end models like CNC plasma cutting machines offer faster cutting speeds.

- Precision and accuracy: For more intricate designs, a machine with precise control, such as a portable CNC plasma cutting machine, may be required.

Plasma Cutting Services and Applications in Different Industries

If you’re looking for plasma cutting services near me, many companies specialize in offering both plasma cutting and engraving services. In addition to cutting, plasma cutting can also be used for creating detailed designs like plasma cutting laser cut gate designs, plasma cutting gate design, and even plasma cutting for home décor.

Plasma cutting is a versatile and efficient method of cutting metals with a range of applications in multiple industries. From creating intricate metal sheet laser cutting designs to larger-scale projects, plasma cutting is an essential process. By understanding the plasma cutting machine types, pricing, and benefits, businesses and individuals can make informed decisions about which cutting method is best suited for their needs.

Plasma Cutting

Discover the plasma cutting machine from ES HAJI & CO. for high-quality, precise, and fast cutting solutions. Perfect for industrial and custom projects, our machines offer reliable performance for various metal types and thicknesses.

Product Brand: E S HAJI And CO

Product Currency: INR

Product In-Stock: InStock

5