What is Springback in Sheet Metal Bending?

Sheet Metal Bending is a critical process in manufacturing, involving the plastic deformation of sheet metal to achieve a desired shape. One common challenge in this process is springback, where the metal partially returns to its original shape after bending. Understanding and managing springback is essential for achieving precise and consistent results.

What Causes Springback in Sheet Metal Bending?

Springback occurs due to the elastic recovery of the material. During bending, a combination of elastic and plastic deformation happens. While plastic deformation causes the metal to hold its new shape, the elastic portion tries to return to its original position, leading to springback. Factors influencing springback include:

- Material type and thickness

- Bend radius and angle

- The method used for sheet metal bending

Key Aspects of Sheet Metal Bending

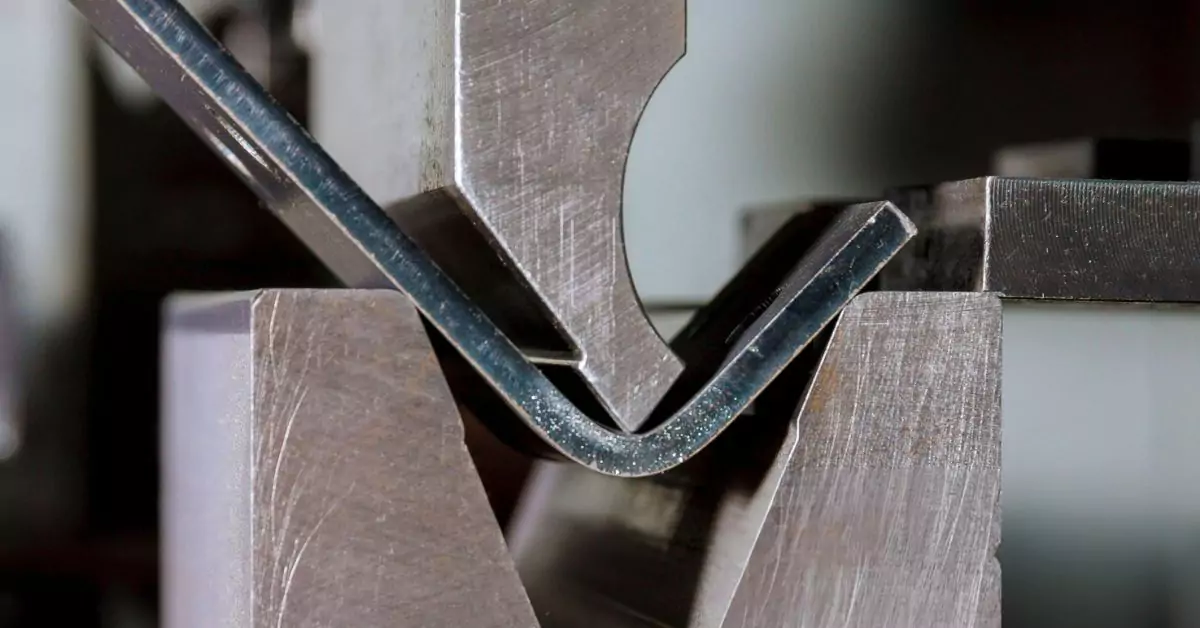

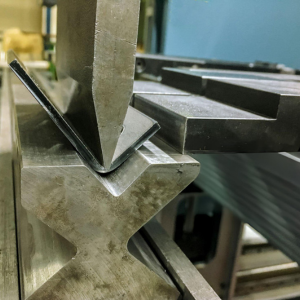

The sheet metal bending process involves using tools such as a press brake or a sheet metal bending machine to apply force. Modern equipment is designed to minimize springback by providing precise control over the bending operation. To better understand this, refer to resources like a sheet metal bending process pdf or utilize advanced software like sheet metal bending SolidWorks for simulation.

Types of Bending in Sheet Metal

Types of Bending in Sheet Metal

Understanding the types of bending in sheet metal is vital to controlling springback. Common types include:

- V-bending

- U-bending

- Roll bending

Each method has specific applications and springback behaviors.

Sheet Metal Bending Rules

Adhering to sheet metal bending rules can help mitigate springback. These rules include:

- Using the correct sheet metal bending radius calculation

- Ensuring proper material selection, such as choosing the best steel for sheet metal bending

- Applying over-bending techniques to compensate for springback.

How to Calculate and Mitigate Springback

Sheet Metal Bending Calculations

To accurately predict springback, manufacturers use formulas and tools such as:

- Sheet metal bending calculation formulas

- Tools like a sheet metal bending calculator

- Advanced software for sheet metal bending radius calculation

Bend Allowance and Bend Deduction

Bend Allowance and Bend Deduction

Understanding sheet metal bending allowance formula is crucial. Bend allowance is the material length required for bending, which is adjusted to reduce springback.

Sheet Metal Bending Tools

Using high-quality sheet metal bending tools and machines can significantly reduce errors caused by springback. These tools include manual setups and automated machinery with springback compensation features.

Applications and Practical Solutions

Springback management is crucial in various industries, from automotive to aerospace. Accurate sheet metal bending operations ensure the production of reliable and durable components.

For companies looking to optimize their processes, services like sheet metal bending near me often provide tailored solutions using advanced machines and techniques.

Springback is a natural phenomenon in sheet metal bending, but with proper understanding, calculations, and tools, it can be effectively managed. Using advanced resources like a sheet metal bending machine project report pdf, or software solutions for sheet metal bending drawing, can further enhance precision and reduce material waste.

Overcoming Springback Challenges in Sheet Metal Bending

Managing springback in sheet metal bending requires a combination of precise calculations, the right tools, and expert techniques. By understanding the material properties, adhering to sheet metal bending rules, and utilizing advanced machinery like a sheet metal bending machine, manufacturers can achieve the desired accuracy and reduce errors. For businesses seeking reliable bending solutions, E S HAJI & CO offers tailored services and innovative technologies to ensure top-quality results for various applications, from custom designs to large-scale industrial needs.

Partnering with Experts for Accurate Sheet Metal Bending

Springback can pose significant challenges in sheet metal bending, but with the right expertise and tools, it is manageable. By leveraging advanced machinery such as sheet metal bending tools and adhering to precise sheet metal bending calculations, manufacturers can achieve impeccable results. E S HAJI & CO specializes in delivering accurate and reliable bending solutions, ensuring every project meets high standards of quality and precision, regardless of complexity.

Sheet Metal Bending

E S HAJI & CO provides advanced sheet metal bending solutions with state-of-the-art machines, precision tools, and expert guidance for diverse industrial applications. From sheet metal bending calculation excel to modern machinery, we ensure accuracy and efficiency in every project.

Product Brand: E S HAJI And CO

Product Currency: INR

Product In-Stock: InStock

5