What is the Mechanical Cutting Process?

Mechanical Cutting stands as one of the most fundamental manufacturing processes across industries worldwide. From precision machining in aerospace to everyday metalworking in construction, understanding mechanical cutting methods is essential for anyone involved in manufacturing, engineering, or fabrication.

We will explores what mechanical cutting entails, the various types of mechanical cutting processes available, and how different mechanical cutting tools and equipment work together to shape materials with precision and efficiency.

Understanding Mechanical Cutting

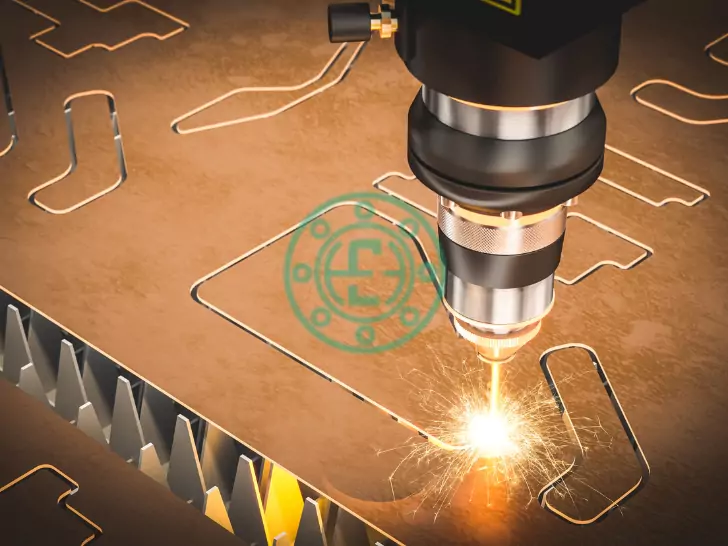

Mechanical Cutting is a material removal process that uses physical force to separate or shape materials through direct contact between cutting tools and workpieces. Unlike thermal or chemical cutting methods, mechanical cutting relies on the application of mechanical energy to physically remove material chips or sections.

The process involves mechanical cutting machines that apply controlled force through various mechanical cutting tools to achieve desired shapes, sizes, and surface finishes. This method offers exceptional precision and versatility, making it suitable for a wide range of materials including metals, plastics, composites, and wood.

Types of Mechanical Cutting Processes

- Sawing: Sawing represents one of the most common mechanical cutting methods, utilizing toothed blades to cut through materials. Band saws, circular saws, and reciprocating saws each offer unique advantages for different applications. The cutting action involves multiple small cutting edges that progressively remove material as the blade moves through the workpiece.

- Shearing: Shearing cuts materials by applying opposing forces that cause fracture along a predetermined line. This process is particularly effective for sheet metals and thin materials. Mechanical shearing equipment includes guillotine shears, rotary shears, and bench shears, each designed for specific material thicknesses and cutting requirements.

- Milling: Milling operations use rotating multi-point cutting tools to remove material from workpieces. This versatile mechanical cutting process can create complex shapes, slots, holes, and surface finishes with high accuracy. CNC milling machines have revolutionized this process by offering automated precision control.

- Turning: Turning involves rotating the workpiece while a single-point cutting tool removes material to create cylindrical shapes. Lathes are the primary mechanical cutting machines used for turning operations, capable of producing both external and internal cylindrical surfaces.

- Drilling: Drilling creates circular holes using rotating cutting tools called drill bits. This fundamental mechanical cutting method is essential in virtually every manufacturing application, from simple through-holes to complex multi-diameter bores.

Key Factors Affecting Mechanical Cutting Performance

Cutting Speed and Feed Rate: The relationship between cutting speed and feed rate significantly impacts cut quality, tool life, and production efficiency. Optimal parameters depend on material properties, tool geometry, and desired surface finish.

Tool Material and Geometry: Mechanical cutting tools must be selected based on workpiece material characteristics. High-speed steel, carbide, and ceramic cutting tools each offer distinct advantages for different applications. Tool geometry, including rake angles and relief angles, affects cutting forces and chip formation.

Workpiece Material Properties: Material hardness, toughness, and thermal conductivity influence cutting parameters and tool selection. Understanding these properties helps optimize the mechanical cutting process for maximum efficiency and quality.

Machine Rigidity and Precision: The mechanical cutting equipment’s structural integrity directly impacts cutting accuracy and surface finish quality. Rigid machine construction minimizes vibrations and deflections that can compromise cut quality.

Advantages and Disadvantages of Mechanical Cutting

Advantages

Mechanical cutting offers several compelling benefits. The process provides excellent dimensional accuracy and surface finish quality when properly executed. Most mechanical cutting tools with names like end mills, drill bits, and turning tools are readily available and cost-effective. The process generates minimal heat compared to thermal cutting methods, reducing material distortion risks.

Mechanical cutting methods also offer exceptional versatility, capable of processing a wide range of materials from soft plastics to hardened steels. The process can achieve tight tolerances and complex geometries that other cutting methods cannot match.

Disadvantages

However, mechanical cutting does present certain limitations. Tool wear is inevitable, requiring regular replacement and maintenance. The process typically operates at slower speeds compared to some alternative cutting methods. Additionally, mechanical cutting generates physical chips and debris that require proper handling and disposal.

Certain hard or brittle materials may be challenging to cut mechanically without special considerations for tool selection and cutting parameters.

Industrial Applications of Mechanical Cutting

- Automotive Manufacturing: The automotive industry relies heavily on mechanical cutting for engine components, transmission parts, and chassis elements. Precision boring, turning, and milling operations create critical components that must meet strict quality standards.

- Aerospace Industry: Aerospace applications demand exceptional precision and surface quality. Mechanical cutting processes create turbine blades, structural components, and landing gear parts from advanced materials including titanium alloys and composites.

- Construction and Infrastructure: Construction projects utilize mechanical cutting for structural steel fabrication, concrete cutting, and pipe preparation. Large-scale mechanical cutting machines handle heavy materials efficiently while maintaining accuracy requirements.

- Medical Device Manufacturing: Medical device production requires extremely precise mechanical cutting operations to create surgical instruments, implants, and diagnostic equipment components. The process must maintain sterile conditions and achieve micron-level tolerances.

The Future of Mechanical Cutting Technology

Mechanical cutting continues evolving through technological advancements. Smart manufacturing integration allows real-time monitoring and optimization of cutting parameters. Advanced tool coatings extend tool life and enable higher cutting speeds.

Automation and robotics are increasingly integrated with mechanical cutting equipment, improving consistency and reducing labor requirements. E S HAJI & CO. and other forward-thinking companies are embracing these technological improvements to enhance their mechanical cutting capabilities.

Additive-subtractive hybrid manufacturing combines 3D printing with mechanical cutting processes, enabling new design possibilities and improved efficiency.

Maximizing Your Mechanical Cutting Success

Understanding mechanical cutting fundamentals enables better decision-making in tool selection, parameter optimization, and process planning. Whether selecting mechanical cutting machines for a new facility or optimizing existing operations, knowledge of cutting principles ensures successful outcomes.

The key lies in matching cutting methods to specific application requirements while considering material properties, quality standards, and production volumes. With proper planning and execution, mechanical cutting processes deliver reliable, precise, and cost-effective manufacturing solutions across diverse industries.

Contact us now to stay updated on the latest advancements and techniques in mechanical cutting processes!